11. Procedure

11.1 Sample Preparation

Blank matrix samples (strawberry (SB), wheat flour

(WF) and leek (LK)) used for validation experiments

were purchased in local retail stores and were homog-

enized with an Ultra-Turrax homogenizer, extracted and

cleaned-up prior to sample preparation. Matrix extracts

were used as matrix blank samples and dilution solvents

for matrix-matched calibration. Ready to use Thermo

Scientific QuEChERS extraction kits were used for

sample preparation, and contained 4 g MgSO

4

, 1 g

NaCl, 1 g trisodiumcitrate dehydrate and 0.5 g disodi-

umcitrate sesquihydrate for buffered extraction of target

compounds. Pre-prepared clean-up tubes contained

1200 mg MgSO

4

, 400 mg PSA and 400 mg C18 for

increased clean-up efficiency for more complex matrices

such as leek. The same QuEChERS protocol was applied

for all of the matrices.

11.1.1 Homogenization of Matrices

11.1.1.1 Select larger amount of strawberry (~500 g)

and bunch of leek matrices and put into an

appropriate size beaker and label it.

11.1.1.2 Attach the G25 dispergation tool to the

Ultra-Turrax homogenizer. (For better recovery

for some unstable compounds cryogenic

homogenization is advised).

11.1.1.3 Start homogenization at middle rotation speed

(speed level 2–3) and continue to form a

smooth homogenate.

11.1.2 Sample Extraction and Clean-up

11.1.2.1 Weigh 10 g sample into a 50 mL QuEChERS

extraction tube containing 4 g MgSO

4

, 1 g

NaCl, 1 g trisodiumcitrate dehydrate and 0.5 g

disodiumcitrate sesquihydrate.

11.1.2.2 Add 200 µL 5000 ng/mL internal standard

#141 to the samples.

11.1.2.3 Add 10 mL ACN to SB and LK samples. For

WF, first add 20 mL H

2

O to the samples, let it

completely wet the sample and then add 10 mL

ACN to it.

11.1.2.4 Shake samples for 10 min on a horizontal

shaker and centrifuge with 5000 rpm for 5 min.

Transfer supernatant (~8 mL) into the 15 mL

QuEChERS clean-up tubes containing 1200 mg

MgSO

4

, 400 mg PSA and 400 mg C18.

11.1.2.5 Vortex for 1 min and centrifuge samples with

5000 rpm for 5 min.

11.1.2.6 Collect supernatant and transfer 1 mL into a

GC vial for instrumental analysis.

11.1.2.7 Add 50 µL sorbitol solution (protectant) and

20 µL 5000 ng/mL injection standard (BFB) to

the GC vials prior to injection.

11.2 GC-MS/MS Analysis

Sample measurements were carried out using the

TRACE 1310 gas chromatograph coupled to the TSQ

8000 Triple Stage Quadrupole Mass Spectrometer

(Pesticide Analyzer). For instrument control, analysis,

data review and reporting TraceFinder 3.1 software

was used.

11.2.1 GC method settings

The injector settings were as follows:

Injector:

Thermo Scientific

™

TriPlus RSH Autosampler

with 10 μL injection syringe

Liner:

PTV Baffle Liner (Siltek), Deactivated,

2 mm ID

×

2.75 mm OD

×

120 mm Length

(recommended to be changed after

40 injections of matrix samples)

Injection mode:

splitless PTV, basic mode

Carrier mode:

constant flow

Inlet temp:

75 °C

Split flow:

50 mL/min

Splitless time:

1 min

Injection volume:

1 μL

Plunger strokes:

3

Air filling mode:

auto

Carrier flow:

1.2 mL/min

PTV injection time:

0.1 min

PTV transfer rate:

2.5 °C/s

PTV transfer temp:

300 °C

PTV transfer time:

3 min

PTV cleaning rate:

14.5 °C

PTV cleaning temp:

330 °C

PTV cleaning time:

20 min

PTV cleaning flow:

75 mL/min

PTV cleaning phase:

post cycle temperature cool down

The GC oven settings were as follows:

Carrier gas:

1.2 mL/min Helium (constant flow)

PTV cleaning phase:

post cycle temperature cool down

4

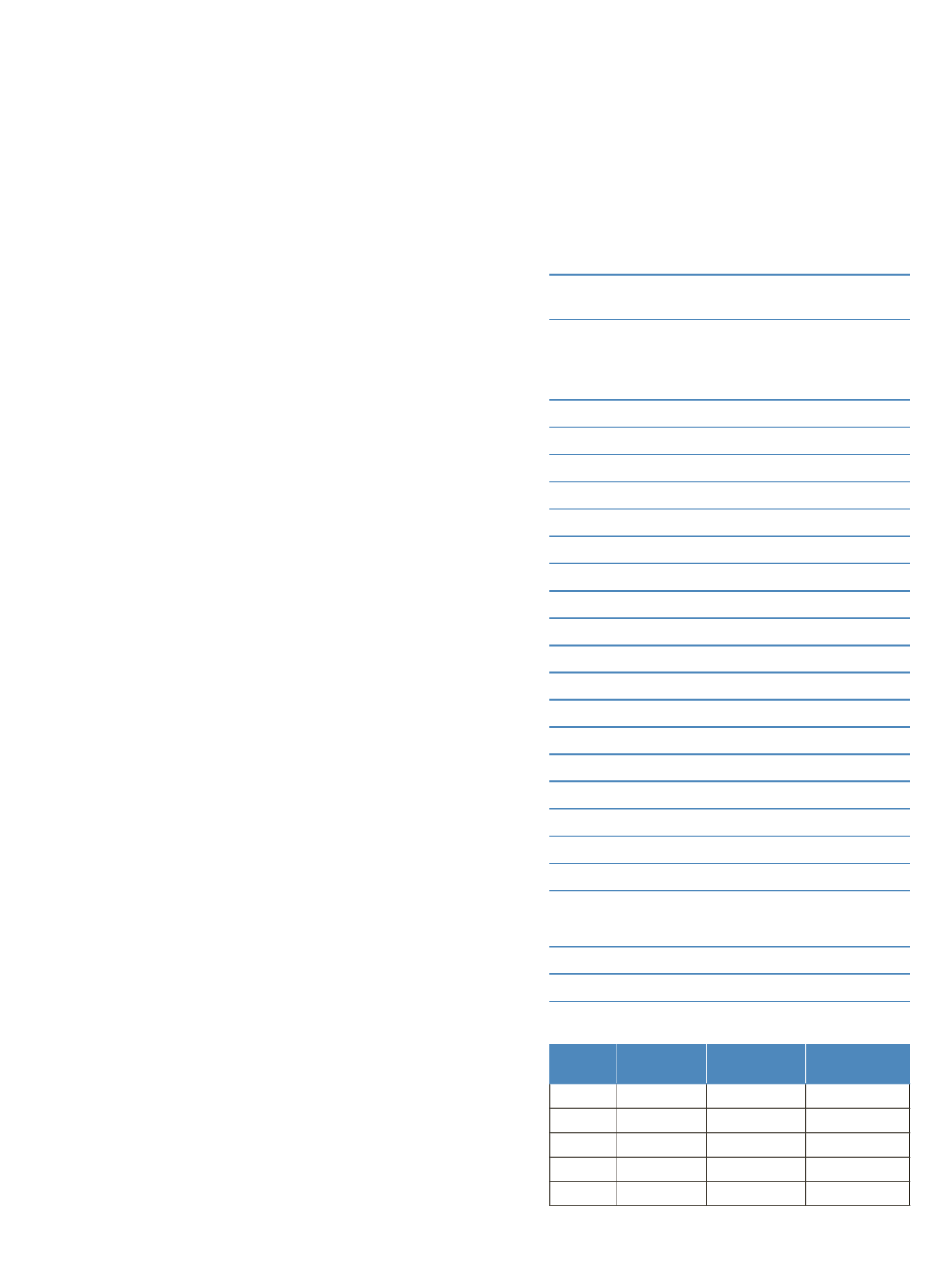

Table 1. GC temperature programming

#

Rate

[°C/min]

Temperature

[°C]

Hold Time

[min]

Initial

40

1.5

1

25

90

1.5

2

25

180

0

3

5

280

0

4

10

300

5