3

2

This technical note describes results obtained from an

endurance mechanical test performed on “Instant Connect”

modules and typical analytical reproducibility and

accuracy provided by the TRACE 1300 Series GC.

Analytical reproducibility was also measured after switching

modules of the same type in the same application, as

might happen when an injector module is replaced with a

new one in a routine laboratory to keep a contaminated

instrument up and running.

Experimental

A TRACE 1310 GC instrument equipped with various

SSL and FID modules was used in all of the experiments,

and all “Instant Connect” modules are identified by specific

serial numbers for easier tracking in the lab. Four different

modules were alternated in these experiments.

The GC was equipped with a Thermo Scientific AS 1310

liquid autosampler. All tests were performed using a

synthetic mix of normal alkanes ranging from C

10

to C

40

in hexane, at a concentration of approximately 10 ppm

(10 ng/μL) and using helium as carrier gas. A 1 μL aliquot

of sample was injected in splitless mode into a standard

glass-wool packed tapered liner, while the injector

temperature was maintained at 300 °C. Splitless time

was 0.8 minutes. The FID detector temperature was set

to 350 °C.

A Thermo Scientific TraceGOLD

™

column TR-5, 15 m x

0.25 mm id x 0.25 μm, was used in all experiments. Oven

temperature was set at 50 °C for 0.5 min and then ramped

up to 340 °C at 20 °C/min, with two minutes of isothermal

time at the final temperature. A Thermo Scientific Dionex

™

Chromeleon

™

Chromatography Data System was used for

setting all method parameters, data acquisition, and data

processing.

Results and Discussion

System analytical reproducibility and accuracy

The analytical reproducibility was evaluated using two

new “Instant Connect” modules, a SSL injector

(module serial number S/N: 712100036) and a FID

detector (S/N: 712300088), by injecting the synthetic

hydrocarbon mix automatically (ten repetitions). Results in

terms of peak area and retention time repeatability are

summarized in Tables 1 and 2. No discrimination for both

volatile and high boiling compounds was seen. As shown

in Table 1 the recovery, calculated using C

20

peak area as

reference, is close to 100% along the full range of

volatility. Absolute peak area relative standard deviation

is far below 1% for all hydrocarbons. All injector and

detector modules incorporate a new generation of

miniaturized gas controls. These integrated electronic

devices ensure precise control of the inlet pressure and the

flow throughout the column, further contributing to the

excellent reproducibility of retention times. As indicated

in Table 2, the standard deviation is below a thousandth of

a minute. This level of reproducibility is a clear indication

of the accurate temperature profile and column flow

maintained during the ramp and the precise thermo-

regulation of the GC oven. Overall results show full

recovery of hydrocarbons and excellent data precision.

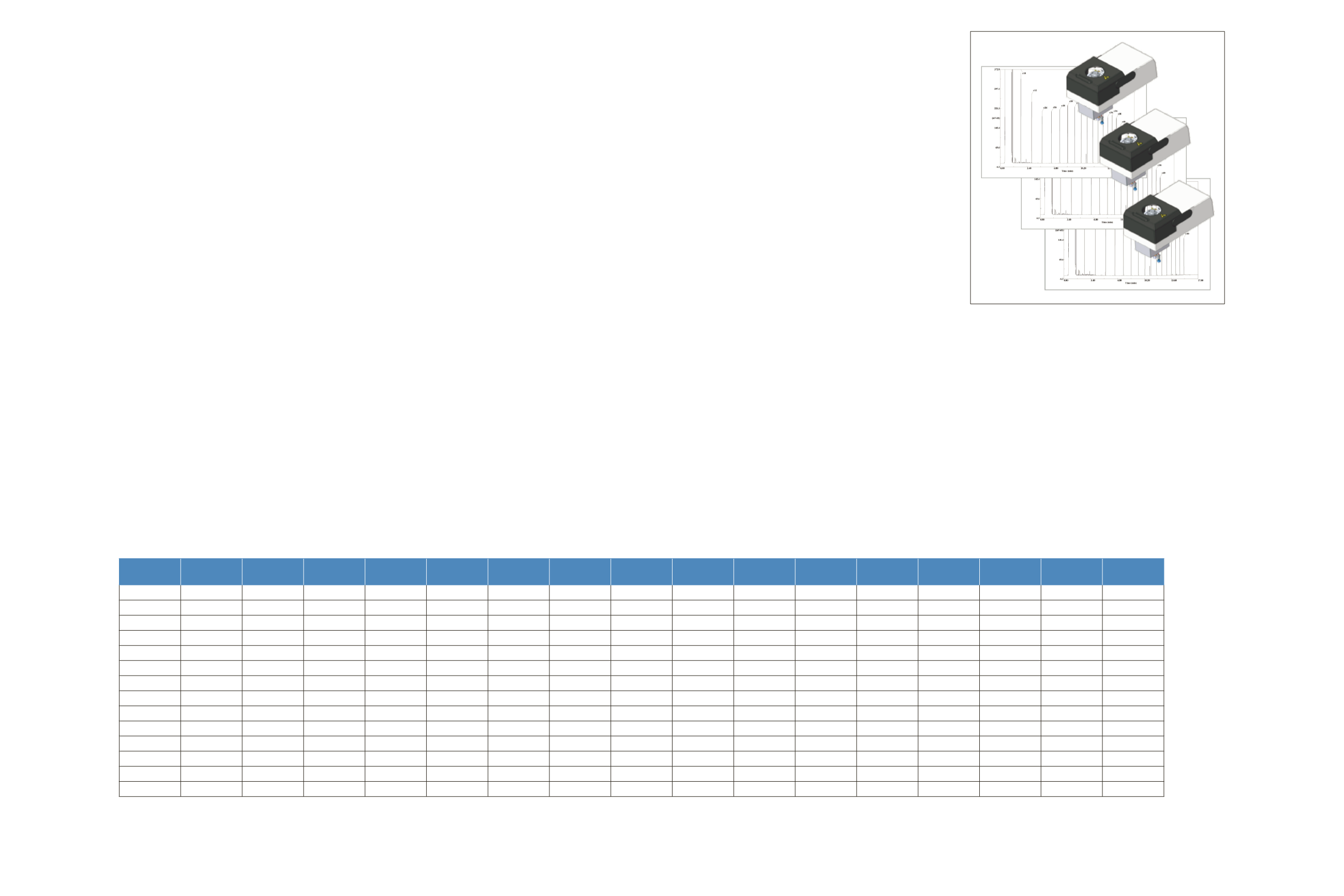

Table 1. Instrument configuration SSL S/N 712100036 and FID S/N 712300088. Absolute peak area RSD% far lower than 1%. Recovery,

measured as ratio vs C

20

average area, at 100% for the whole range of hydrocarbons

SSL 712100036

/ FID 712300088

nC10

nC12

nC14

nC16

nC18

nC20

nC22

nC24

nC26

nC28

nC30

nC32

nC34

nC36

nC38

nC40

Injection 1

2600304

2647767

2600941

2619188

2552750

2565809

2543886

2535687

2512699

2527008

2602759

2597807

2534441

2564855

2470270

2525384

Injection 2

2610605

2657856

2601653

2623404

2568557

2579380

2565938

2565679

2545232

2560614

2636265

2629734

2557462

2596729

2495209

2563483

Injection 3

2602666

2653832

2599714

2626029

2553641

2577265

2561577

2558672

2542703

2555406

2632496

2630095

2555743

2580475

2480864

2538819

Injection 4

2636572

2683702

2632897

2656448

2593709

2602685

2584957

2575384

2558834

2574920

2649582

2640082

2566623

2593858

2490053

2549873

Injection 5

2623737

2668679

2617130

2639475

2575209

2588255

2568857

2566489

2551218

2570336

2641759

2632243

2559472

2591033

2487269

2545848

Injection 6

2628675

2671731

2625320

2647746

2586155

2602674

2584119

2578956

2563433

2577945

2652932

2644762

2572449

2600568

2495549

2560371

Injection 7

2633245

2675436

2621623

2640507

2579749

2601553

2603546

2589030

2566470

2580193

2651340

2644782

2575086

2615870

2515378

2552861

Injection 8

2622426

2667773

2618401

2631007

2571368

2588047

2571982

2568771

2543992

2565899

2635937

2628421

2556233

2599156

2491820

2552234

Injection 9

2627383

2675413

2624978

2646945

2578061

2590137

2578171

2582555

2553973

2565982

2637795

2636002

2561603

2598494

2504800

2575965

Injection 10

2621650

2664829

2611668

2634863

2576839

2592681

2577082

2571091

2552087

2567396

2634338

2631176

2560023

2590260

2497076

2558360

Average (counts)

2620726

2666702

2615432

2636561

2573604

2588848

2574011

2569231

2549064

2564570

2637520

2631510

2559913

2593130

2492829

2552320

SD

12355

10941

11571

11889

12894

12092

15913

14767

15078

15223

14298

13319

11161

13430

12358

13908

RSD %

0.47%

0.41%

0.44%

0.45%

0.50%

0.47%

0.62%

0.57%

0.59%

0.59%

0.54%

0.51%

0.44%

0.52%

0.50%

0.54%

Recovery %

101%

103%

101%

102%

99%

100%

99%

99%

98%

99%

102%

102%

99%

100%

96%

99%

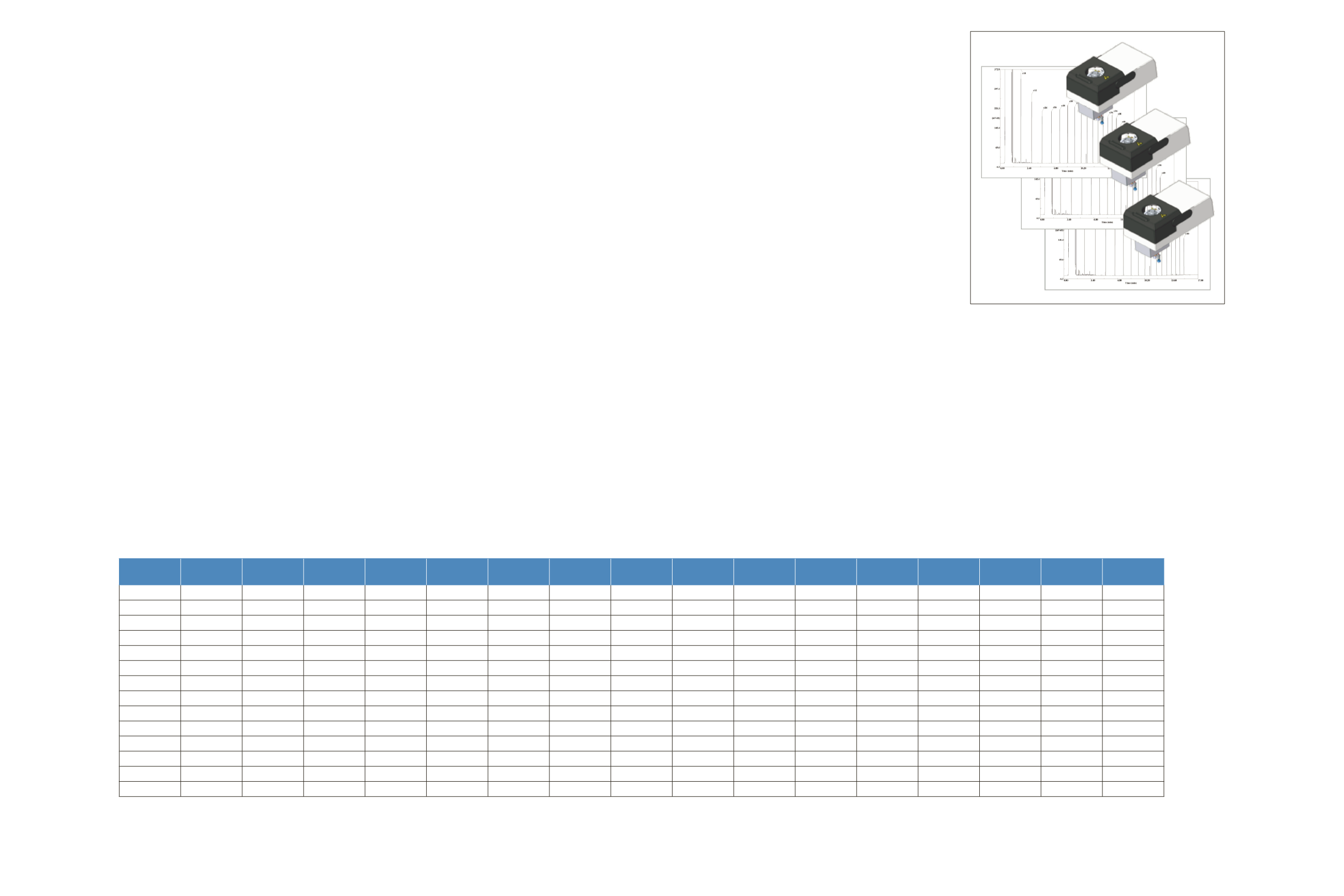

Figure 1. Module-to-module repeatability. Modules store all

of their calibration information allowing minimum variation if

replaced on a system.

Module-to-module reproducibility

To simulate a situation where a laboratory needs to quickly

replace a module, such as to avoid interrupting instrument

throughput for maintenance, the “Instant Connect” SSL

injector module (S/N: 712100036) was replaced by a new

module (S/N: 712300021). This required cooling and

powering down the instrument, disconnecting the column

from the original SSL injector module, removing the module

and plugging in the new one, connecting the column, and

powering up the TRACE 1310 GC again. Electronic gas

control permits an automated leak check to be performed

to guarantee that no artifacts are introduced by this

manual operation. The reduced thermal mass GC design

allows a quick recovery of injection-ready conditions after

instrument power-up. As a result, the GC was ready to

resume analytical injections again in only nine minutes

after it was originally powered down. A blank GC cycle

was programmed before injecting samples again, which is

good practice to ensure the entire flow path was not

affected by air introduced during module replacement.

An automated sequence of 10 injections was performed

immediately after the module replacement along with

collecting data. The instrument was then stopped again,

and the FID detector module (S/N: 712300088) was

replaced by a new one (S/N: 712300126). After a blank

run, another sequence of 10 injections completed the

experiments. Tables 3 and 4 and Figure 1 summarize the

repeatability results for the three different instrument

configurations. Variations in peak area measured as a

delta of the average counts are in the range of a few

percentages when changing either the injector or the FID

detector. Such a variation, for many applications, is well

below the required limit of a system suitability check,

eliminating the need to recalibrate the GC system as a

whole. The retention time variations are in the range of a

few hundredths of a minute or even less with no impact

on component retention time.