7

6

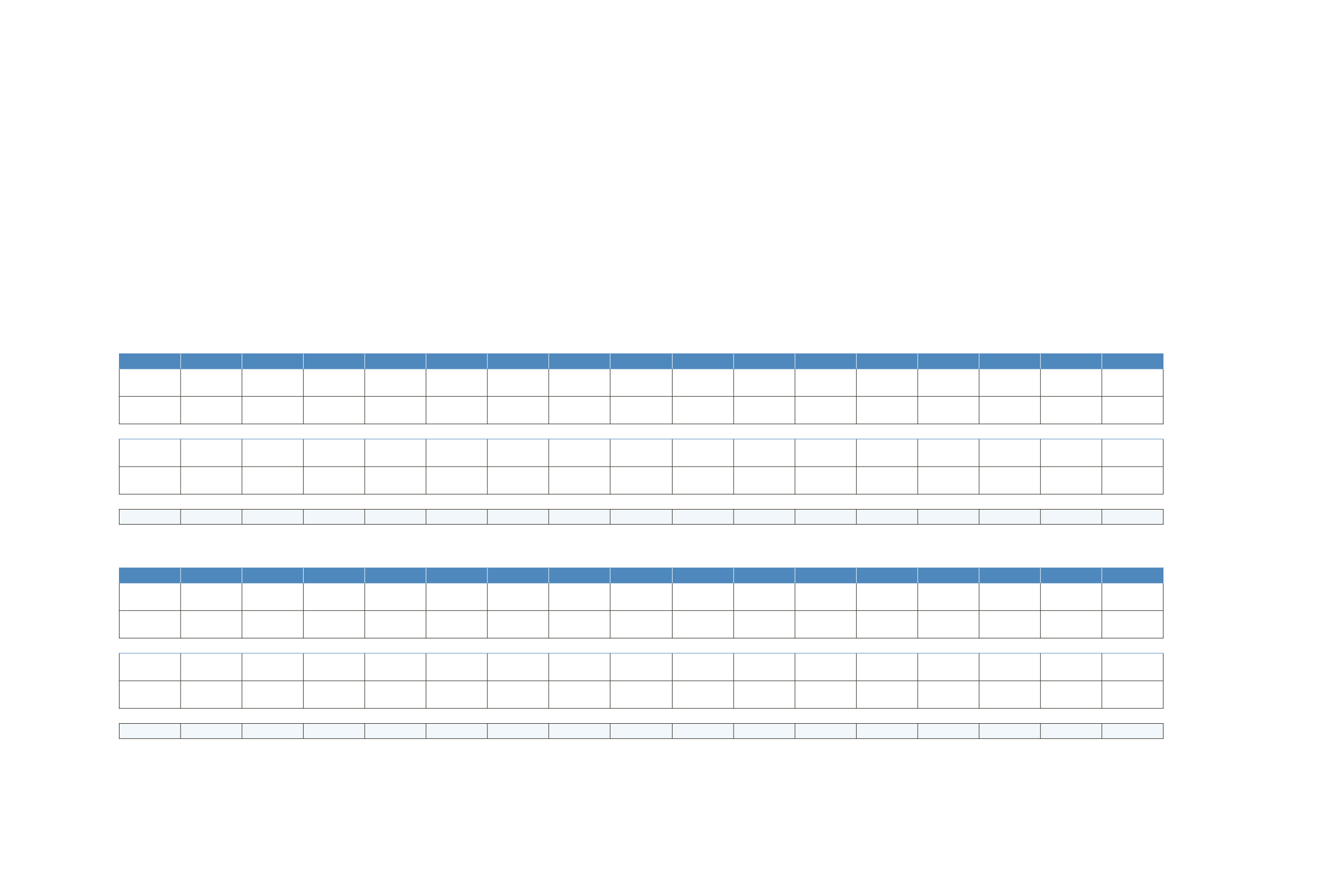

Injector module endurance test

Module robustness was tested mechanically by

having ten different operators repeatedly insert

and remove the module. The operators had

widely varied skills and knowledge, with some

subjects having no prior GC experience. Two

operators were from the shipping department,

and two worked in order processing. Two had

limited GC knowledge and were the Quality

Manager and Product Manager of a different

product line. Finally, two engineers and two GC

scientists that also presided over all of the tests

participated. The module subjected to the test

was the “Instant Connect” SSL injector (S/N:

712300021), and the sequence applied by each

operator included powering off the GC,

removing the module, inserting the module, and

powering up the GC until it reached stand-by

condition. The total average test sequence time

was six minutes. Each operator repeated this

cycle ten times.

After each operator finished his or her cycle, the

column was connected again to the SSL injector

and FID detector, followed by a double blank

run. Ten automated injections of the

hydrocarbon mix completed the test. Tables 5

and 6 include the results of the last two runs

performed before starting the ruggedness test

and the two initial runs of the new sequence. It

is useful to note that the new sequence was

started the day after the last sequence of

injections was recorded. The variations of both

absolute peak areas and retention times indicate

the module performed perfectly without

requiring any maintenance.

nC10

nC12

nC14

nC16

nC18

nC20

nC22

nC24

nC26

nC28

nC30

nC32

nC34

nC36

nC38

nC40

Injection 9 before

IC swap

2754987

2779540

2709468

2720590

2662466

2694642

2671418

2666034

2640542

2660383

2748956

2756412

2705301

2768808

2658421

2670870

Injection 10 before

IC swap

2751265

2775027

2708032

2732281

2677453

2705799

2688053

2684329

2667261

2684684

2755387

2771243

2709754

2772642

2651536

2665536

Injection 1 after

IC swap

2767372

2791927

2719553

2738439

2664499

2693367

2672357

2657758

2643338

2655810

2738028

2745997

2704789

2768416

2664390

2670998

Injection 2 after

IC swap

2756768

2787601

2711585

2738364

2687682

2720242

2699762

2690563

2663741

2677520

2756966

2774421

2711745

2765971

2664631

2676359

Variation

-0.59%

-0.61%

-0.43%

-0.23%

0.48%

0.46%

0.58%

0.99%

0.90%

1.08%

0.63%

0.91%

0.18%

0.15%

-0.48%

-0.20%

Table 5. Variation in peak area before and after 100 times module replacement cycle

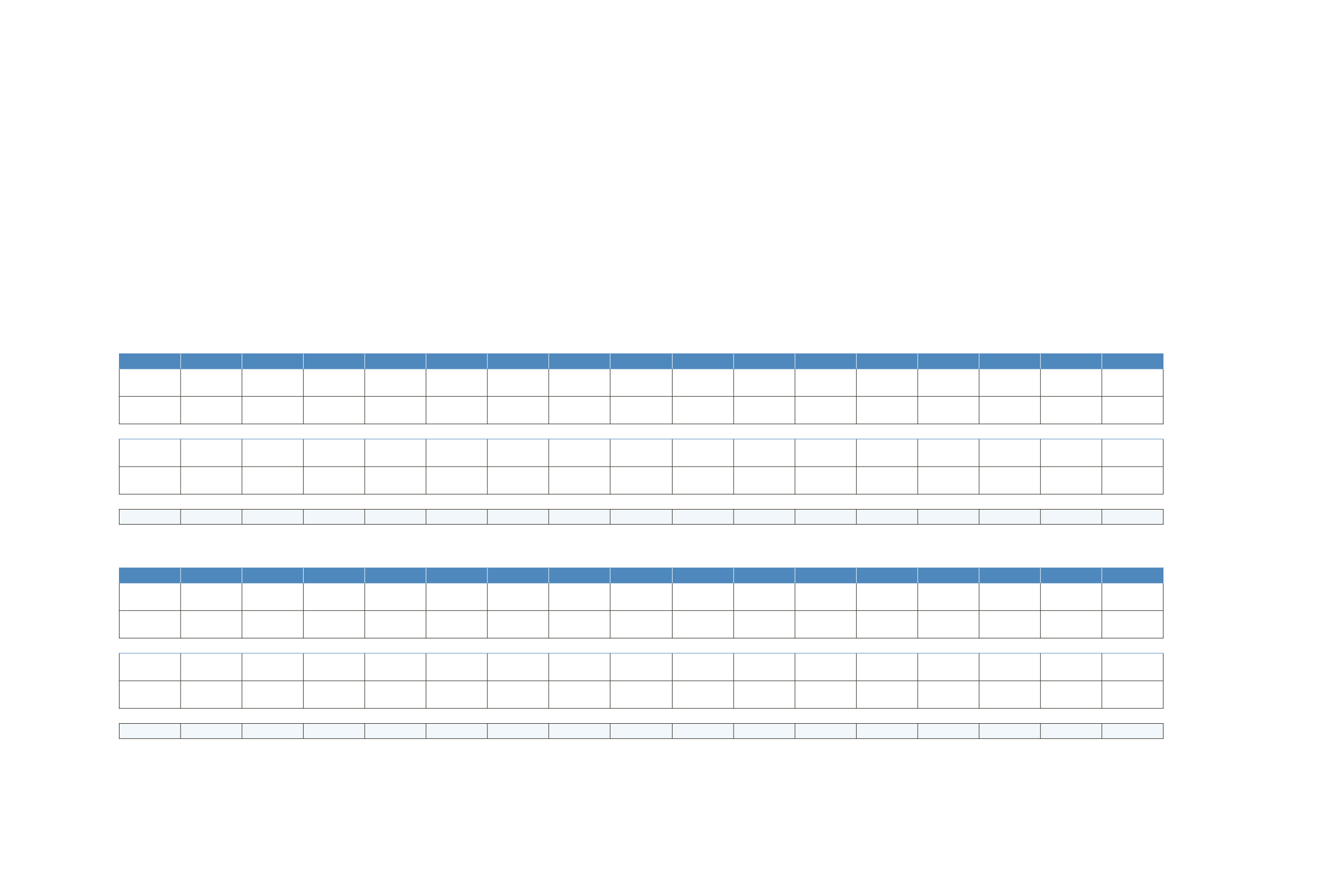

nC10

nC12

nC14

nC16

nC18

nC20

nC22

nC24

nC26

nC28

nC30

nC32

nC34

nC36

nC38

nC40

Injection 9 before

IC swap

2.562

3.935

5.253

6.447

7.525

8.507

9.408

10.235

11.003

11.717

12.383

13.010

13.598

14.153

14.678

15.185

Injection 10 before

IC swap

2.563

3.933

5.255

6.445

7.523

8.508

9.407

10.237

11.005

11.717

12.383

13.012

13.595

14.154

14.677

15.185

Injection 1 after

IC swap

2.563

3.935

5.253

6.447

7.525

8.507

9.408

10.238

11.003

11.718

12.385

13.010

13.598

14.153

14.678

15.183

Injection 2 after

IC swap

2.563

3.935

5.253

6.447

7.523

8.508

9.407

10.237

11.003

11.718

12.385

13.012

13.600

14.155

14.680

15.187

Variation

-0.03%

-0.04%

0.04%

-0.03%

-0.02%

0.01%

-0.02%

-0.02%

0.02%

-0.01%

-0.01%

0.02%

-0.02%

0.00%

-0.01%

0.01%

Table 6. Variation in retention time before and after 100 times module replacement cycle