4

Automated MAb Workflow: from Harvest Cell Culture to Intact Mass Analysis of Variants

Results

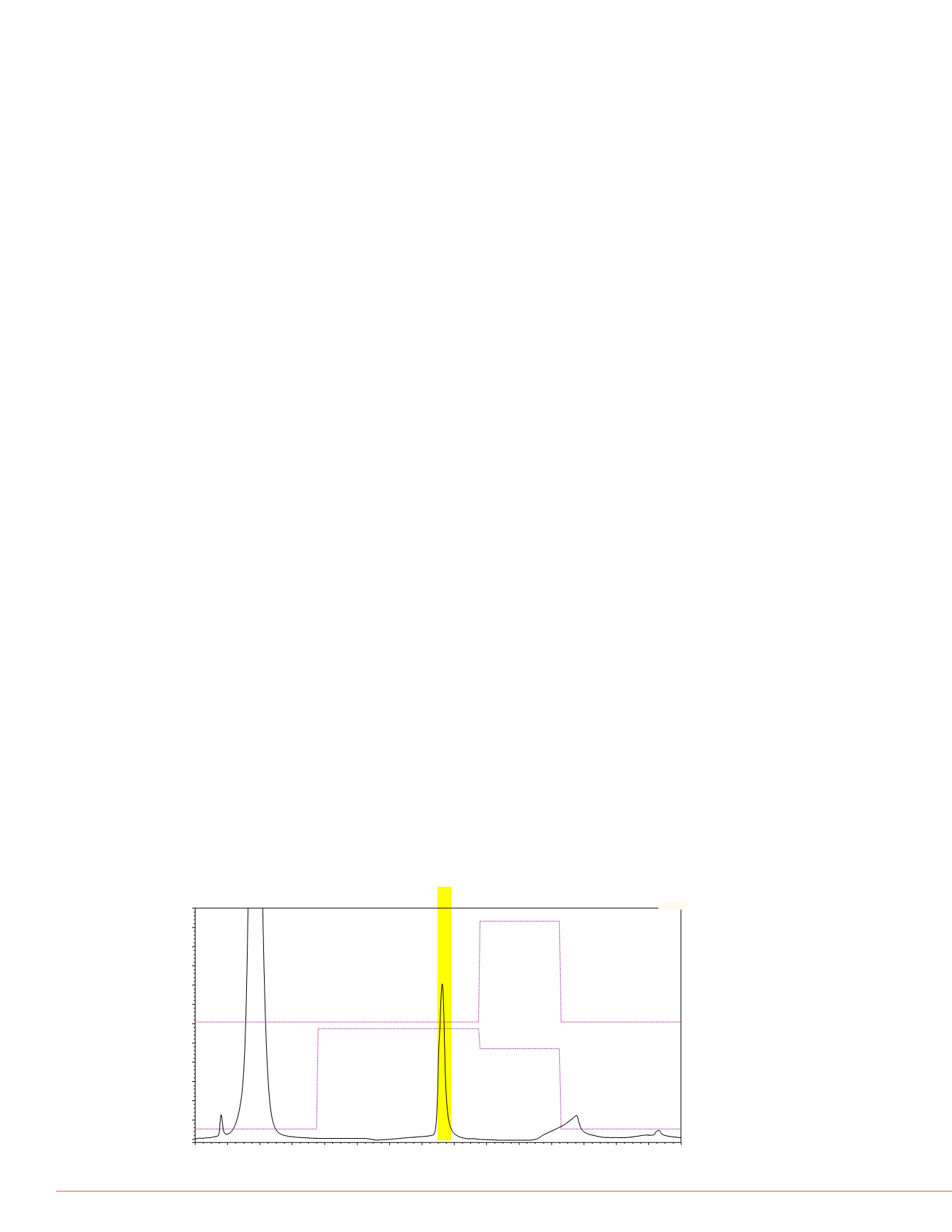

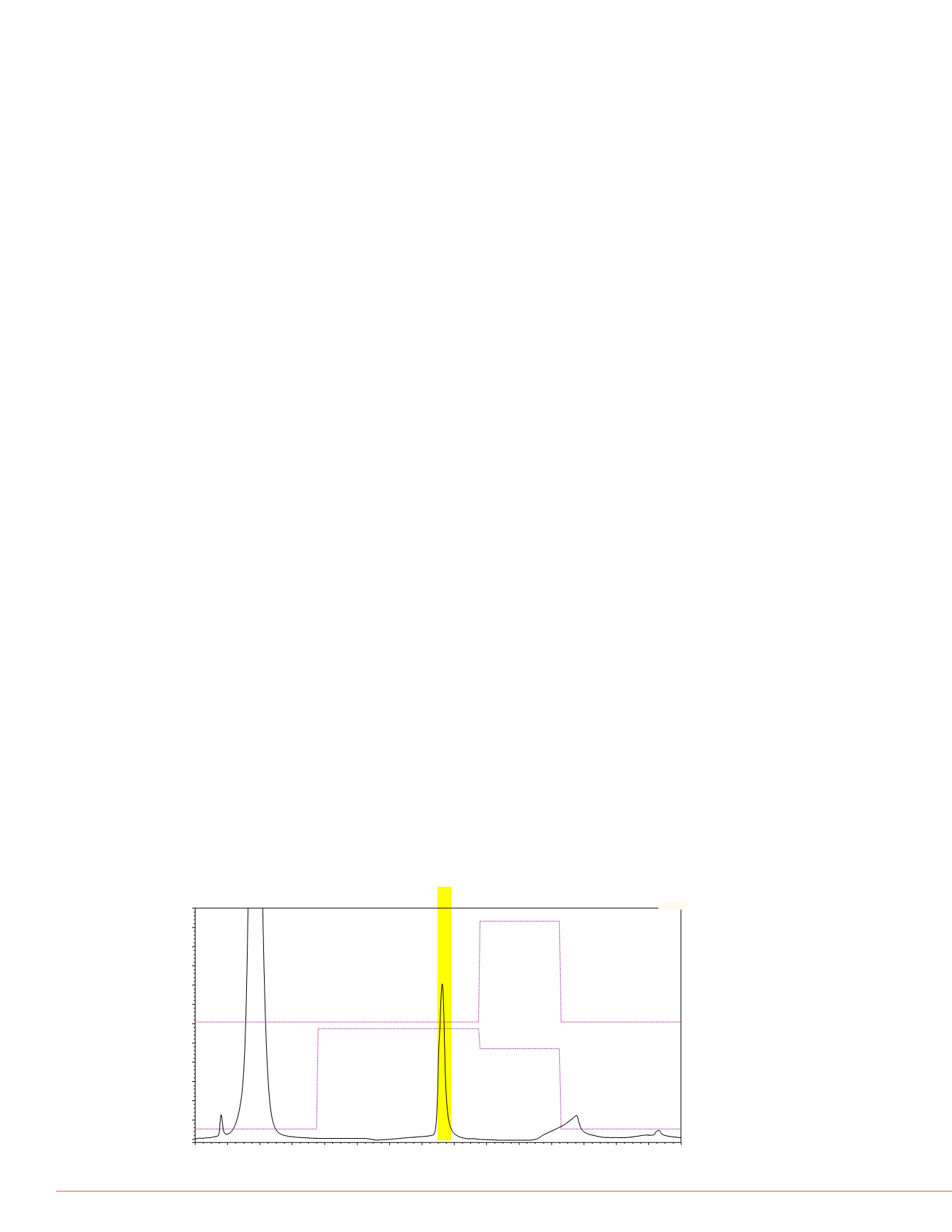

In the first step of the chromatographic separation, HCC was injected onto the

Protein A Affinity column. In order to collect sufficient amounts of IgG material for the

2

D analysis, 50 µL of HCC was injected. The IgG fraction was collected into a

96-wellplate using time-based triggers (Figure 2). The total collection time was

0.1 min. At 2 mL/min flow rate, the total volume collected was 200 µL. Chromeleon

CDS software is capable of fraction collection using UV-based peak triggers, or both

time and peak triggers together. In the configuration presented here, there was a

0.1 min delay time in fraction collection.

A transition sequence was used to switch the valves and direct the flow path to each

2

D analysis column. The

2

D analyses can be either SEC (Figure 3) or IEC (Figure 4).

Collected fractions can be directly injected onto the

2

D column without further

modifications. The injection volume for each

2

D was 25 µL.

The IEC analysis of the Protein-A purified fractions which used a linear salt gradient

revealed many variants in the purified IgG fractions. A one-hour carboxypeptidase

digestion (data not shown) eliminated several peaks and enhanced others,

suggesting the presence of lysine variants. Use of the MAbPac SCX-10 3 µm column

reduced the analysis time from ~60 to 20 min. The total analysis time for all three

chromatographic steps was <60 min, which included the transition programs

between different analyses. All these steps are automated, and therefore multiple

HCC samples can be cycled through without user intervention.

Over the last few years, researchers have demonstrated that pH-gradient-based IEC

is an effective method to separate acidic and basic proteins. In this study, we applied

pH gradient to the separate MAb variants on a MAbPac SCX-10 column. As shown in

Figure 5, separation of at least three variants was achieved. Major peaks 1, 2, and 3

eluted at 19.8, 20.8, and 22.1 min, respectively. Use of the PCM-3000 allowed real-

time monitoring of the pH and conductivity of the eluent during all the analyses. The

pH values for fractions containing Peaks 1, 2, and 3 were 8.5, 8.6, and 8.7,

respectively. These fractions were analyzed on a Q Exactive mass spectrometer

(Figure 6). On-line desalting using a reversed phase monolithic column was carried

out prior to MS detection. The deconvoluted spectra (Figure 7) showed that the major

component in Peak 1 has a 147992.703

m/z

. Adjacent peaks at 148155.503 and

148315.903

m/z

correspond to different glycoforms with 1 and 2 additional hexoses.

The major component in Peak 2 has a 148210.650

m/z

. The delta mass between

Peak 1 and Peak 2 is 128 amu, corresponding to one lysine. Similarly, the delta

mass between Peak 2 and Peak 3 (at

m/z

148248.641) is also 128 amu. These data

suggest that Peak 1 and Peak 2 correspond to lysine truncation variants of Peak 3.

C system using

FIGURE 4. Example of a

2

D SCX separ

from the MAbPac SCX-10, 3 µm, 4 × 5

de the following:

ow rate of

he autosampler

and reconditioned

ludes one of the

ic mobile phase

in using a salt

FIGURE 3. Example of an isocratic

2

collected from the MAbPac SEC-1, 4

FIGURE 2. Example of a

1

D affinity purification of IgG from HCC: the vertical

yellow stripe indicates fractionation time.

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

2.20

2.40

2.60

2.80

3.00

-20

125

250

375

500

625

750

875

1,000

1,125

1,250

1,375

1,500

UV_VIS_1

mAU

min

WVL:280 nm

Flow:2.000 ml/min

%B-ProtA, elute: 0.0 %

100.0

80.0

0.0

%C-ProtA, reequilibrate: 0.0%

20.0

0.0

1- Void-0.351

2- IgG-1.525

GA1

Protein AAffinity Separation Conditions:

Column:AB Poros

®

A 20 µm, 4.6 × 50 mm

Mobile PhaseA: 50 mM NaH

2

PO

4

, 150 mM NaCl, pH 7.5

Mobile Phase B: 50 mM NaH

2

PO

4

, 150 mM NaCl,pH 2.5

Mobile Phase C: Acetonitrile

Gradient:

Wash and equilibration step for 0.75 min at 100% A,

followed by 1 min elution step at 100% B,

followed by 0.5 min regeneration step at 80% B and 20% C

Flow Rate: 2.0 mL/min

Temperature: 30

°

C

0.0

1.0

2.0

3.0

4.0

5.0

6.0

-5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0 mAU

SEC Conditions:

Column: MAbPac SEC-1, 4 × 300 mm

Mobile Phase:50 mM NaH

2

PO

4

, 300 mM NaCl

Flow Rate: 0.3 mL/min

Temperature: 30

°

C

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

-1.00

0.00

1.00

2.00

3.00

4.00

5.00

6.00 mAU

Flow:0.600 ml/min

%B IEC high salt:10.0 %

%C:0.0%

SCX Conditions:

Column: MAbPac SCX-10, 3 µm, 4 × 50 mm

Mobile PhaseA: 20 mM MES, 60 mM NaCl,

Mobile Phase B: 20 mM MES, 300 mM NaCl

Gradient:

linear increase from10 % B to

1 min high salt wash at 100% B

3 min re-equilibration step at 1

Flow Rate: 0.6 mL/min

Temperature: 30

°

C

lumn

formic acid in H

2

O

n was heated to 50

b, a 5 min gradient

SI-MS for intact

was set at 10.

ºC . S-lens level

500. The AGC

.

ing Thermo

ect algorithm for

re produced by

profile for the MAb.

put

m/z

range of

a target mass of

rom the input

m/z

pH-GradientSeparation Conditions:

Column: MAbPac SCX-10, 10 µm, 4 × 250 mm

Mobile PhaseA: 9.6 mM Tris, 11 mM imidazole, a

Mobile Phase B: 9.6 mM Tris, 11 mM imidazole,

Gradient:

3 min pre-equilibration at 40% B

followed by linear increase from40

followed by 7 min high pH wash at

followed by 15 min re-equilibration

Flow Rate: 1.0 mL/min

Temperature: 30

°

C

Fraction Collection Rate: 0.2 min/well

15.0

16.0

17.0

18.0

19.0

20.0

21.0

-5.0

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0 mAU

64%B

1

FIGURE 5. pH gradient separation of