3

Thermo Scienti c Poster Note

•

PN ASMS13_Th544_JCole_E 07/13S

ing of more than 500

etermine the value of a

ion by QuEChERS

0 pesticides in matrix.

levels acceptable by EU

es could be determined to

the diversity of compounds

y control. Furthermore,

akes it attractive to use

ectrometry has emerged as

ides due to its high

e of the chemical diversity

l, or even sufficient for a

th LC and GC sample

spectrometer for the

Drug Administration

range of pesticides,

lection of an appropriate

odified QuEChERS

, which is a sample

1

. The QuEChERS extracts

iculture. For the

5 mL of acetonitrile were

CE™ 1310 Gas

s Spectrometer. A

s used on the TRACE

njector was utilized so that

tical column at as low a

was ramped, volatilizing

ed. A slow ramp of 5 ºC/min

d 280 ºC, which is the

d, to achieve optimal

. Figure 1 shows the total

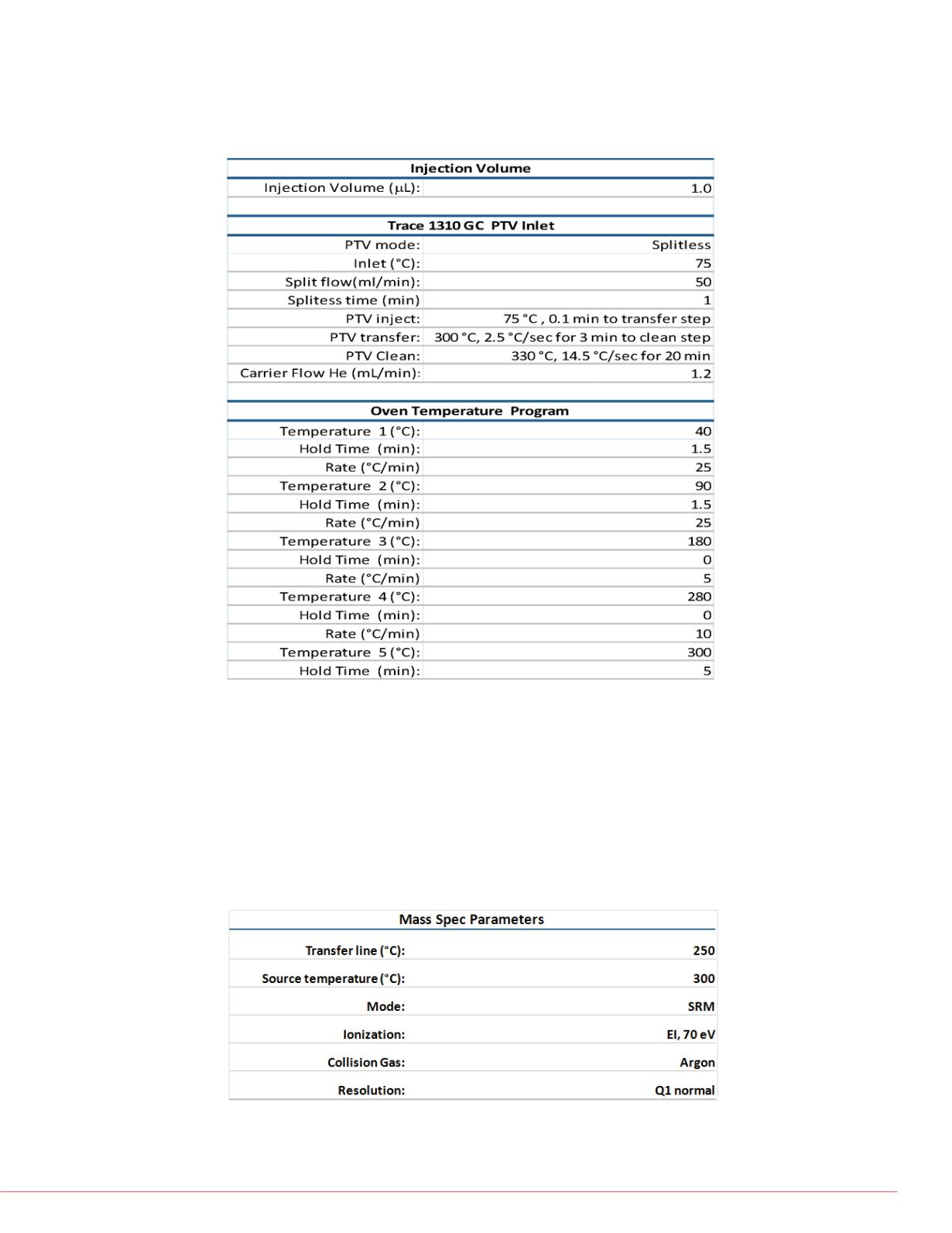

Figure 2 lists the GC

FIGURE 2. Gas Chromatograph Parameters.

LC/MS Instrument Methodol

U-HPLC Method Conditions

Chromatographic analysis was

1250 UHPLC system. The auto

Analytics, Zwingen, Switzerland

Hypersil

™

GOLD aQ column (1

4 is the total ion chromatogram.

FIGURE 5. HPLC Paramete

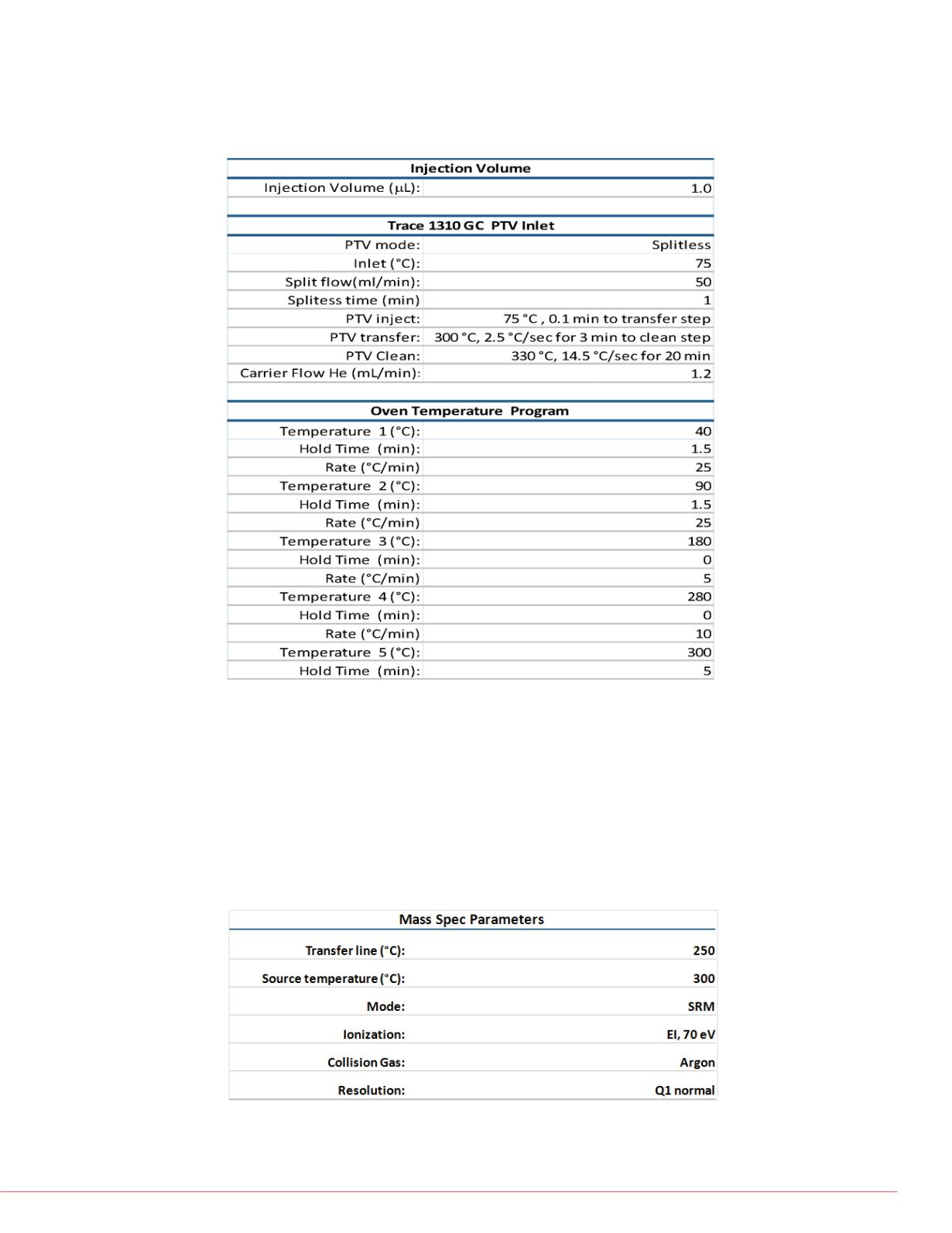

FIGURE 3. GC-Mass Spectrometer Parameters

GC-Triple Quadrupole Method Conditions

Transitions for all pesticides were taken from the Thermo Scientific™ TSQ 8000

Pesticide Analyzer. These transitions were originally developed with the use of

AutoSRM software, which provided automated SRM development with collision

energies optimized to

±

1 eV. Thermo Scientific TraceFinder™ software was used for

acquisition and processing of the extracted samples. Selecting the appropriate

compounds from the pesticide analyzer automatically populated the SRM acquisition

list in the instrument method and the compound processing parameters in the

Thermo Scientific™ TraceFinder™ software processing method. One ion per

compound was used for quantitation and two additional ions were used for ion ratio

confirmation. Figure 3 lists additional MS parameters used.

FIGURE 4. LC/MS Total Ion C

The analytical column used was a Thermo Scientific™ TraceGOLD™ TG-5SILMS,

with dimensions 30 m x 0.25 mm x 0.25 µm. The liner employed was a baffled,

Siltek™ deactivated inlet liner.