4

Sample Analysis (Components Identification)

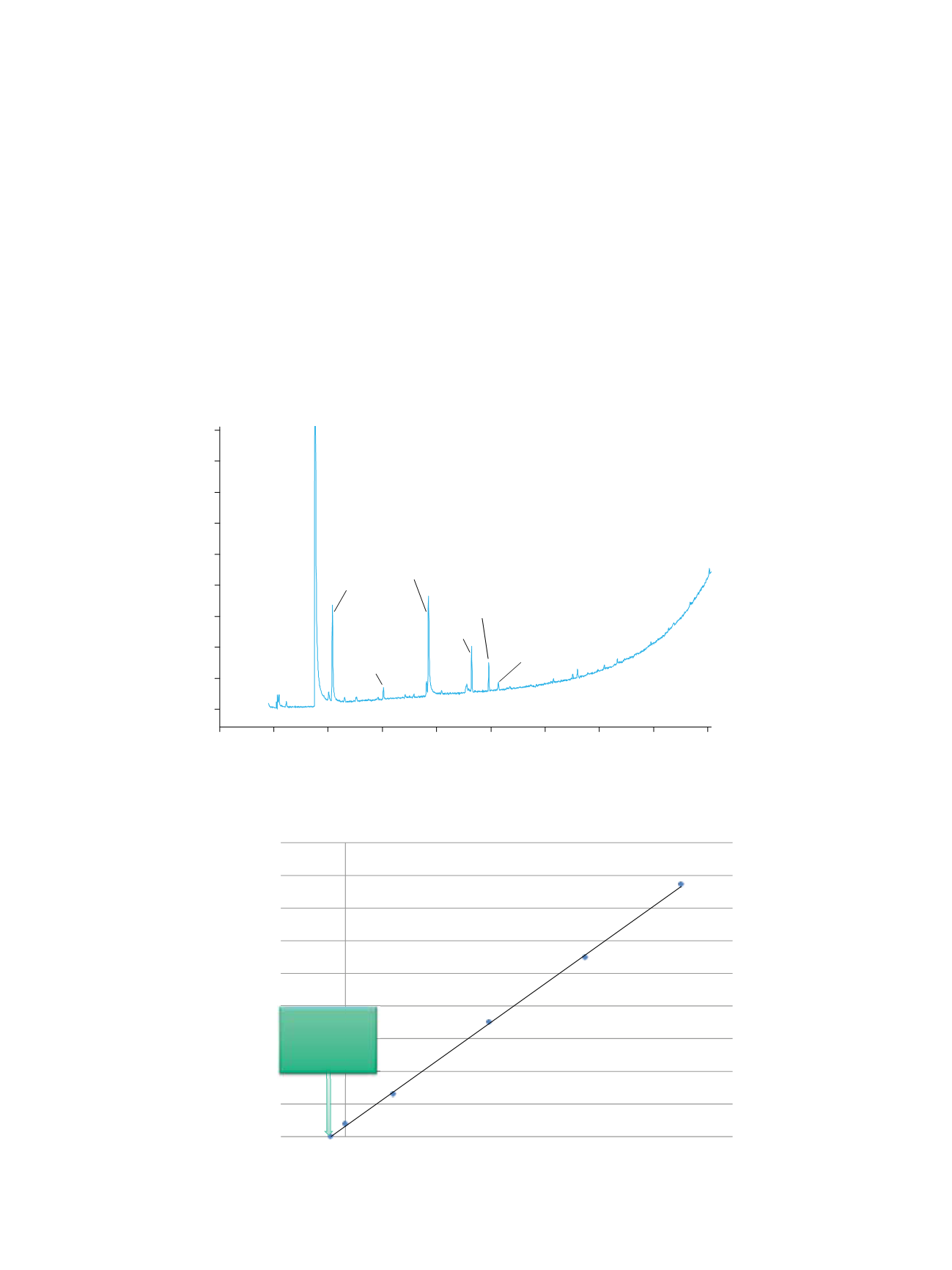

A full-scan chromatogram of the packaging sample

was performed in order to identify the components

possibly present.

Figure 4 shows the presence of numerous residual

solvents. The larger ethanol peak comes from the

croissant itself where ethanol is used as a preservative.

Sample Analysis (Components Quantification)

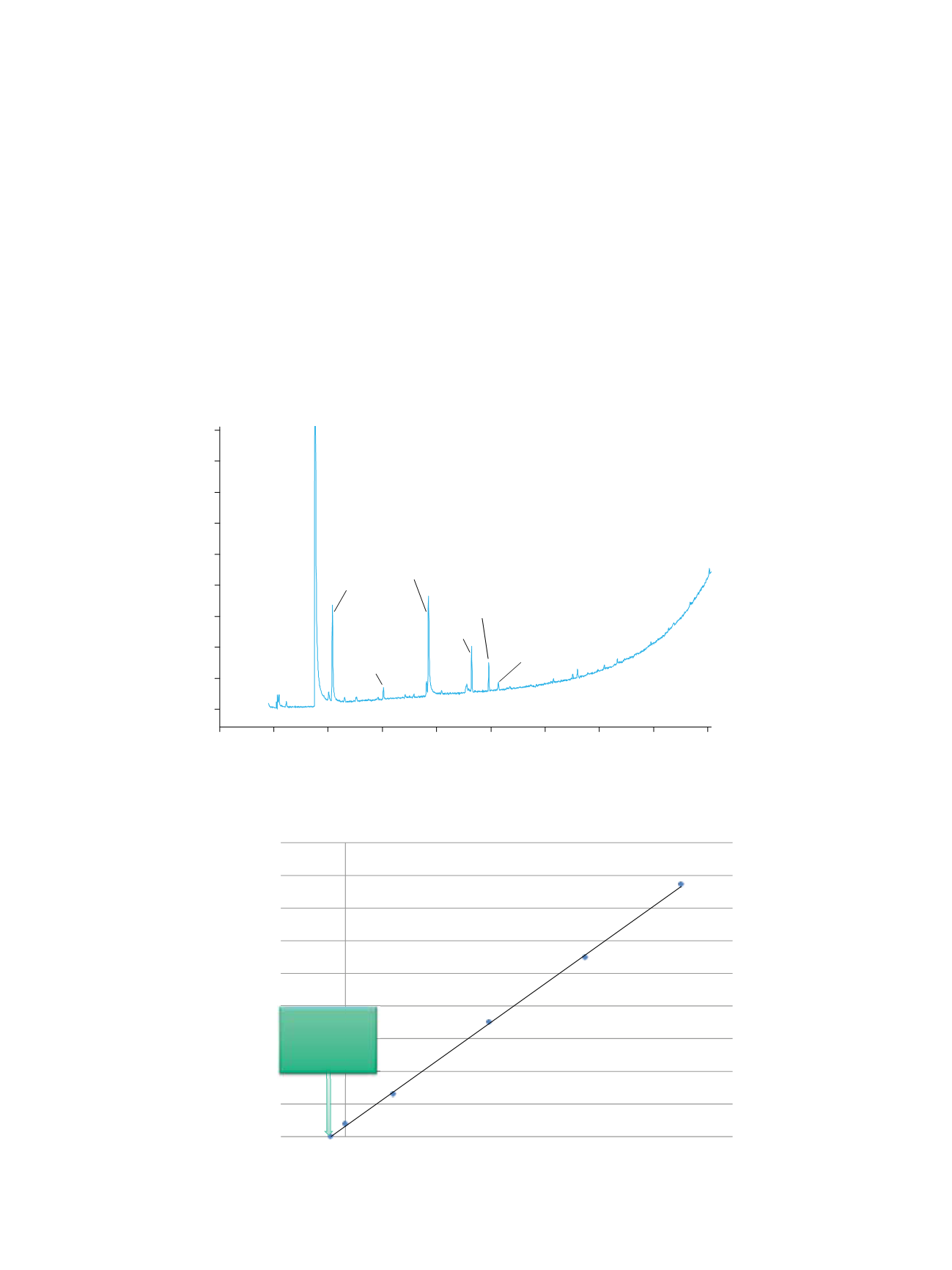

Quantification performed by means of the standard

addition method was carried out for the peaks identified

in the chromatogram in Figure 4. Figure 5 shows the

standard addition calibration curve for

n

-butyl acetate

together with the results of quantification in the sample.

Figure 4. Full-scan sample analysis by headspace.

Table 2 presents the results of the quantification.

In Figure 6, the graphical representation of the

quantification analysis shows that the two main

residual solvents identified in the sample are 1-methoxy

2-propanol and 2-propanol. Their amounts do not exceed

the level of 0.1 mg/m

2

each, while the other detected

residual solvents have been quantified in the level of 0.01

mg/m

2

or lower.

Conclusion

A completely automated method for analyzing and

quantifying VOCs in food packaging materials is

presented. The combination of sample preparation steps

and an analytical step in the same sequence allows high

accuracy in quantification, high sample throughput, and

minimizes error-prone manual manipulations. For the

majority of residual solvents analyzed in this method, their

individual limit of quantitation was below 0.01 mg/m

2

.

RT:

0.00 - 45.28

0

5

10

15

20

25

30

35

40

45

Minutes

5

10

15

20

25

30

35

40

45

50

Methyl cellosolve

Ethyl acetate

2-propanol

Ethanol

1-butanol

1-methoxy 2-propanol

Toluene

Butyric acid ethyl ester

0

500000

1000000

1500000

2000000

2500000

3000000

3500000

4000000

4500000

-0.01

0

0.01

0.02

0.03

0.04

0.05

0.06

Peak Area

Concentration mg/m

2

0.0022 mg/m

2

n-butyl acetate

R

2

= 0.9996

Figure 5. Quantitation via standard addition calibration for n-butyl acetate.