Injection

The ITQ 700 is paired with the Thermo Scientific FOCUS

GC gas chromatograph, which is a single-channel GC

with a standard split/splitless (SSL) injection port. The SSL

inlet temperature was set to 250 °C. A 5 mm ID splitless

liner with a volume of 1.6 mL was selected for the surged

pressure injection. For the surge splitless injection, the

inlet pressure was held at an elevated pressure of 250 kPa

for the 0.5 minute injection (splitless) time. This technique

reduces the vapor cloud of a 2 µL injection from 0.37 mL to

0.19 mL. At an elevated injection flow rate of 4.6 mL/ min,

the liner was swept several times during injection. The target

compounds moved through the inlet so rapidly that they

had less time to interact with the inside walls of the liner.

This minimized the amount of breakdown of the more

fragile pesticides.

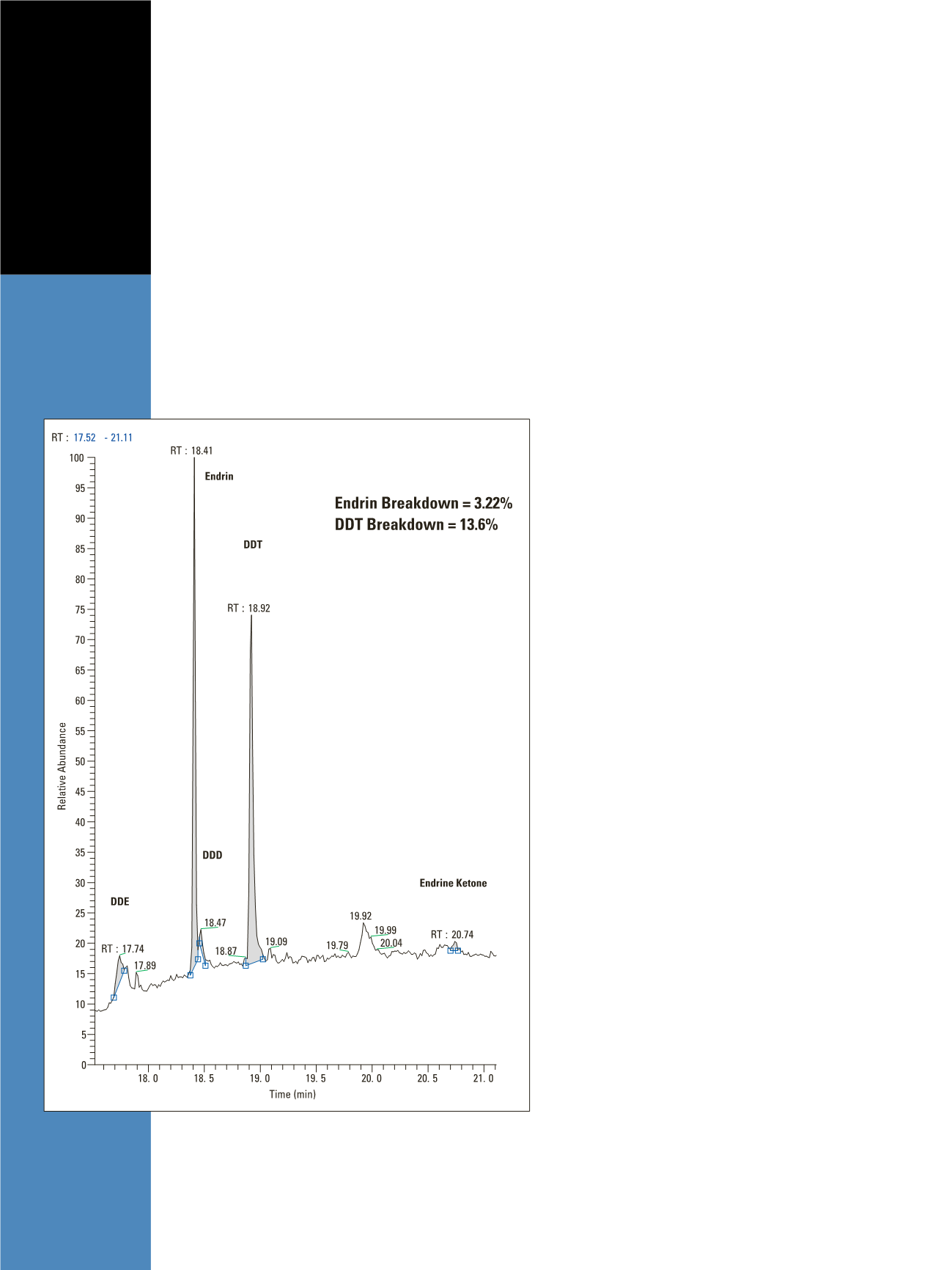

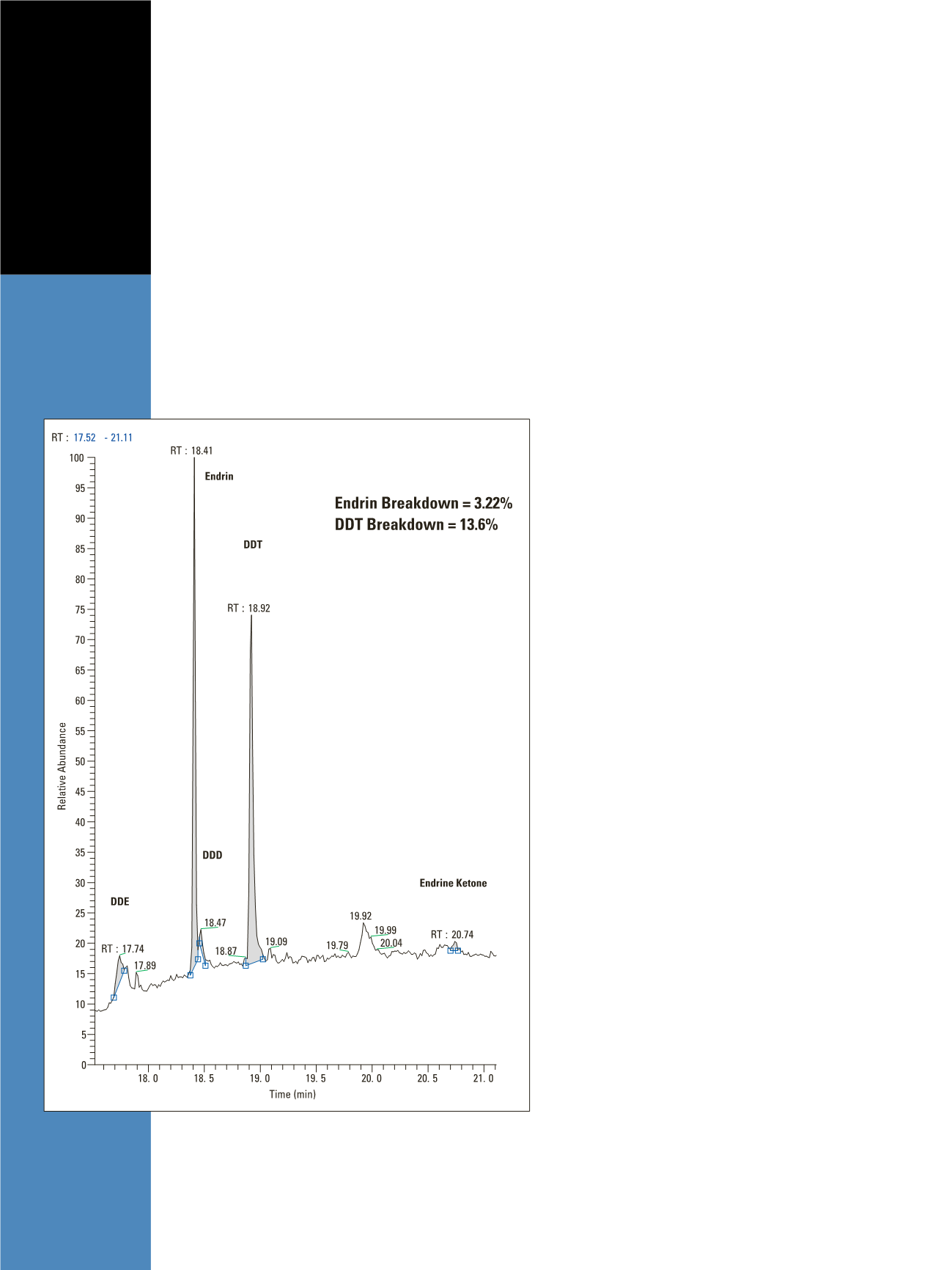

A Performance Solution consisting of endrin and

4,4'-DDT was analyzed as a daily check to determine

system activity. The analysis of endrin, DDT, and their

breakdown products as part of daily quality control can

alert the analyst that the system has developed active sites

and maintenance is needed. Without performing a breakdown

analysis the laboratory may need to continually maintain

the equipment and replace consumables, even when it may

not be needed. Monitoring breakdown can decrease the

cost of running the analysis and save significant amounts

of time.

Endrin breakdown is determined by adding up the

response for the two breakdown products: endrin aldehyde

and endrin ketone and dividing by the total response for

the breakdown products and endrin in percent. The

breakdown products of DDT are DDE and DDD and are

calculated similarly. The breakdown check results showed

< 15% breakdown for both compounds on a daily basis.

For routine use the liner would be changed when the

breakdown of either compound reaches > 20%. The injection

port liner tested showed very good results over a long

period of time without the need for maintenance (Figure 3).

Separation

Chromatographic separation was achieved by using a

35% diphenyl/65% dimethyl polysiloxane column

(0.25 mm x 30 meter, and a film thickness of 0.25 µm

with a 5 m guard column). This column was chosen to

improve the resolution of the more polar compounds.

Some interactions within the stationary phase showed a

loss of some pesticides at concentrations below 100 pg.

The oven was programmed as follows: Initial Temp: 40 °C,

1.5 min, 25 °C/min to 150 °C, 0.0 min, 5 °C/min to 200 °C,

7.5 min, 25 °C/min to 290 °C with a final hold time of

12 min and a constant column flow rate of 1 mL/min. The

entire set of instrument parameters is listed in Table 2.

Detection

The detection of the pesticides was performed using the

ITQ 700 ion trap mass spectrometer with optional MS

n

mode and a variable damping gas option. The MS/MS

scan mode offers significantly enhanced selectivity over

scanning modes such as full scan and selected ion

monitoring (SIM). The ITQ 700 operated in the MS/MS

mode generates unique product ion spectra by collision

induced fragmentation of each of the detected pesticides.

Because of the highly effective elimination of matrix

interfering ions, more accurate results are produced at the

lower levels. The MS

n

parameters for the ITQ 700 are

listed in Table 3. Figures 4 and 5 show a comparison

between a Full Scan TIC and MS/MS extracted ion profile.

Page 4 of 8

Figure 3: System performance check analysis demonstrating endrin

breakdown < 5% and DDT breakdown < 15%