The tube was capped and vortexed for 30 seconds.

The cap was removed and the powder reagents were poured

slowly into the MeCN layer. The cap was tightened

securely on the 50 mL extraction tube, and was vortexed

for 30 seconds until all of the powder reagents were

mixed with the liquid layers. The tube was placed on a

mechanical shaker for 5 minutes and then centrifuged for

5 minutes at 3000 rpm. Next, 11 mL of the top MeCN

layer was removed and transferred to a 15 mL clean-up

tube. This tube was capped and vortexed for 30 seconds

and centrifuged for 5 minutes at 3000 rpm. A 5 mL aliquot

of the top layer was transferred into a clean test tube for

solvent exchange.

Solvent Exchange

The 5 mL aliquot of cleaned-up extract was evaporated to

dryness with a gentle stream of nitrogen at 40 °C in about

two hours. A film formed on top of the solvent layer and

samples required mixing to break the film and continue

the evaporation process. Care was taken to remove the

tube immediately when dried. Approximately 1 mL of

extracted compounds from the tea remained in the tubes

after evaporation. A 900 µL aliquot of hexane/acetone

(9:1) was added and 100 µL of the internal standard,

d10-parathion, was spiked into the organic solution. The

tube was capped and vortexed for 15 seconds. The 1 mL

of extract was transferred to a 2 mL clean-up tube, capped

tightly, and vortexed for 30 seconds. After centrifuging for

5 minutes at 3000 rpm, 200 µL of the lightly colored

extract was transferred to an autosampler vial with a small

glass insert for injection on the ITQ 700

™

. The individual

calibration levels were spiked into each extract for the

calibration curve in matrix before the final cleanup step

(Figure 1).

Page 3 of 8

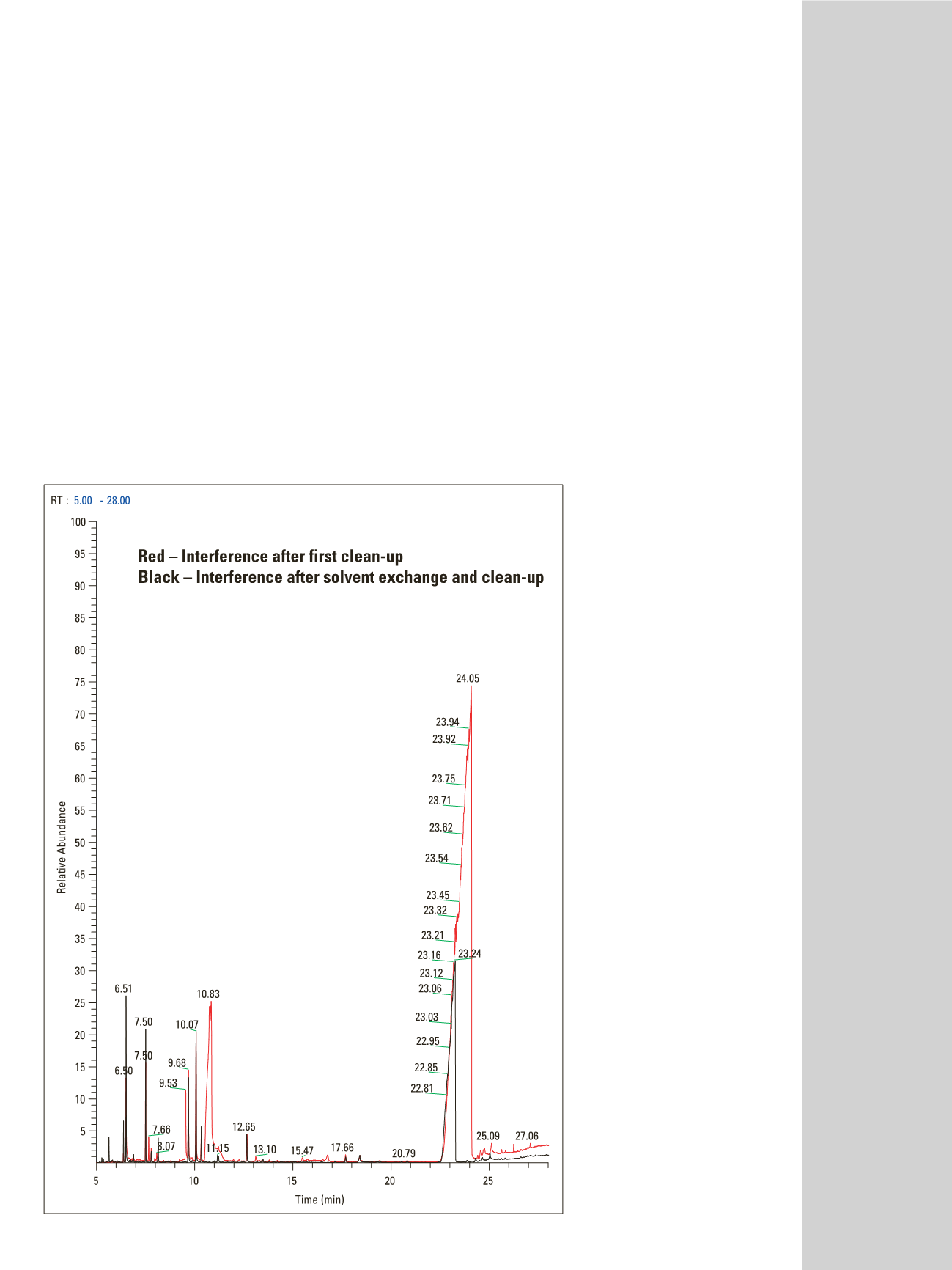

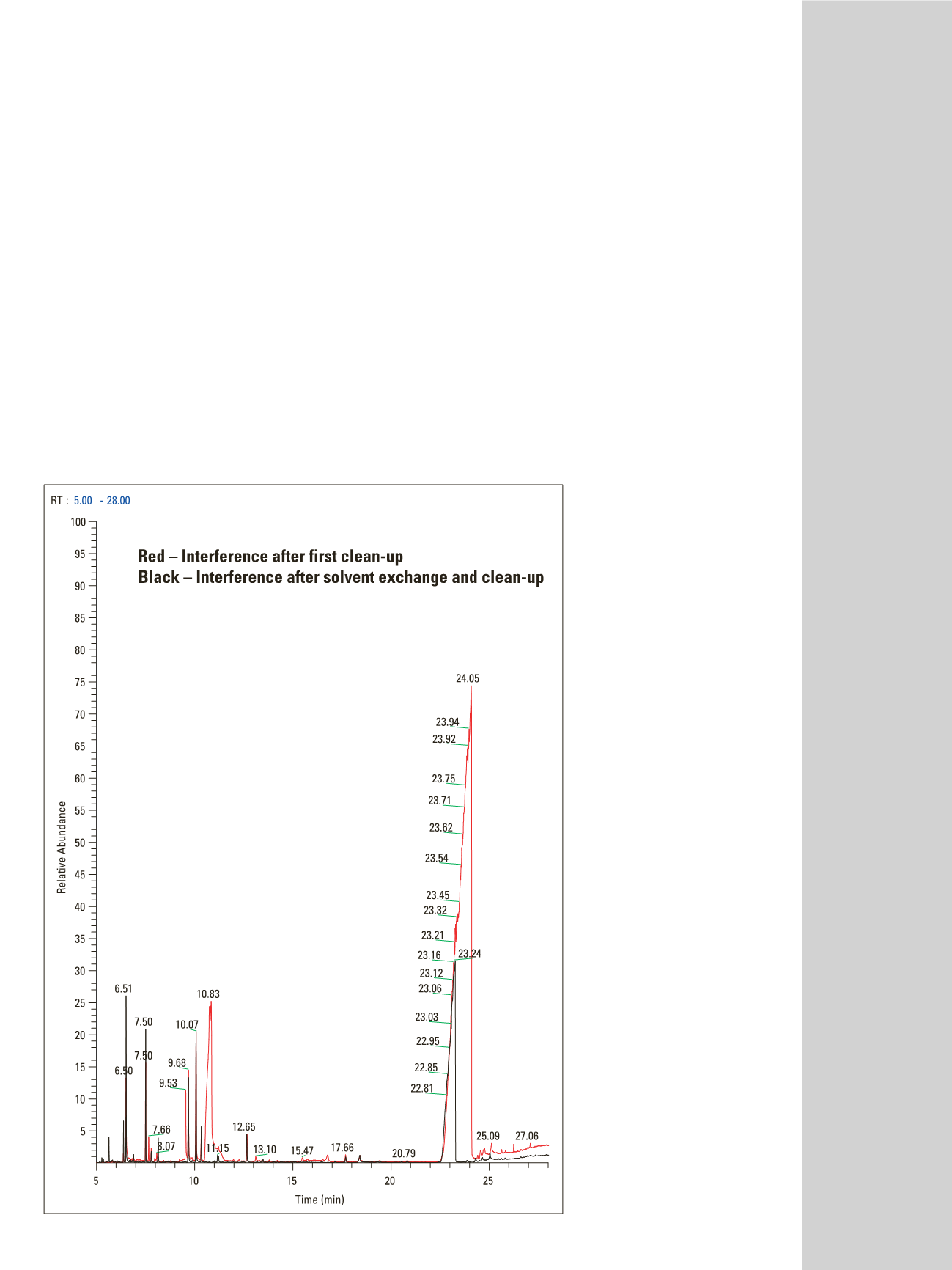

Figure 2: Comparison of a single cleanup

step (red) against solvent exchange/final

cleanup (black)