2

Method Setup

A method was developed for the Thermo Scientific

TRACE

™

1310 Gas Chromatograph and the TSQ 8000

Mass Spectrometer (Table 1).

Table 1. Recommended instrument conditions

TRACE 1310 GC

Injection Volume:

1 μL

Liner:

Siltec baffled liner (P/N 453T2120)

Carrier Gas:

He, constant flow, 1.15 mL/min

Column Type:

20 m, 18 mm ID, 0.18 µm df, TG-XLBMS

(P/N 26079-5780)

Column Oven:

Initial 60 ˚C, hold 1 min. Ramp 30.0 ˚C min to

200 ˚C. Ramp 10.0 ˚C min to 320 ˚C.

Hold 2.0 min.

Transfer Line:

320 ˚C

TRACE 1310 GC PTV program

Injector Temperature: 80 ˚C, Splitless Injection 1 min

PTV Inject:

80 ˚C, 0.1 min. 600 ˚C/min to transfer step

PTV Transfer:

320 ˚C, 5 min, 870 ˚C/min to clean step

PTV Clean:

325 ˚C, 15 min, clean flow 25 mL/min

TSQ 8000 Mass Spectrometer in EI mode

Source Temperature: 350 ˚C

Ionization:

EI, 70 eV

Emission Current:

50 μA

Resolution:

Q1 normal

Collision Gas:

Argon

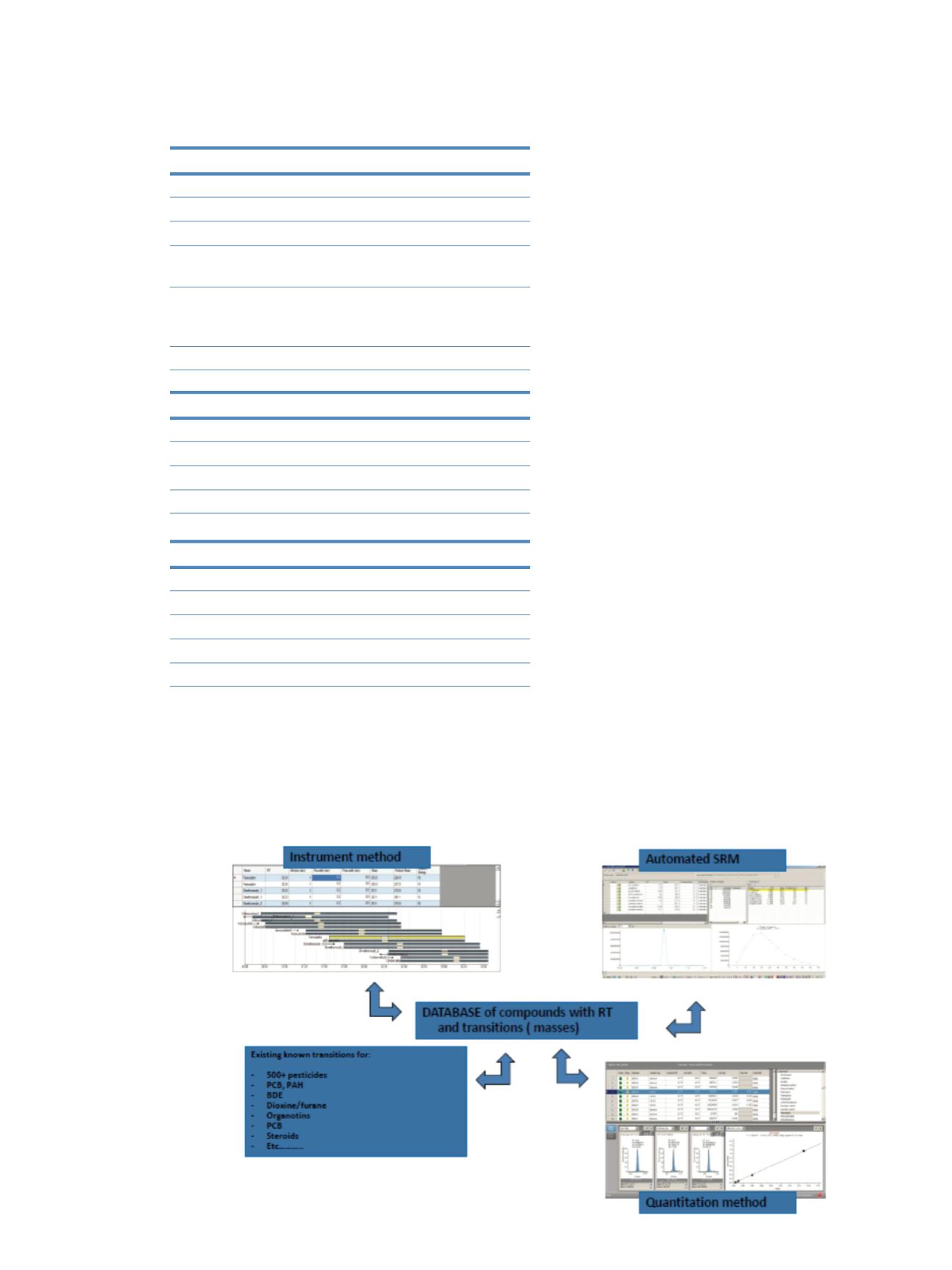

Method Adoption: Mass Spectrometer Acquisition

Method and Quantitation Method

With the TSQ 8000 GC-MS/MS system, the operator can

perform automated SRM method development,

shortening the method development time considerably.

AutoSRM accelerated the method development process.

The optimized parameters were tracked in a clear and

simple way. The program started from a Full Scan

analysis, and the peaks were identified with a library

search. Clicking on each peak revealed a list of most

intense ions, and those were selected to be pushed into a

working list and used for the second injection, the product

ion scan.

The results were again plotted into a chromatogram and,

by clicking on the peaks, the product ions were listed into

a table of decreasing intensity. Finally those product ions

were pushed into a working list, and the final optimization

started where the ions were subjected to increasing

collision energy. This was plotted into a graphical

representation and into a third working list. Selecting this

working list created a SRM method for all compounds,

which was linked to a full instrument method.

Furthermore, the transitions and the retention times were

exported into a compound data base, linking the method

automatically to a quantitative method in Thermo

Scientific TraceFinder

™

software.

A comprehensive explanation is found in application brief

AB52998: Introducing AutoSRM: MRM Simplicity for

High Performance Results.

3

Tuning

A complete automated tuning was provided with the

TSQ 8000 GC-MS, ensuring reproducible tuning, even

when different users were working with the instrument.

The tune contained an automated leak check using the

ratio between the native air/water background and a

metered amount of air introduced into the source.

The tuning was saved to the instrument automatically and

the last tune file was coupled to the instrument method by

default, but it was also perfectly possible to attach another

tune file to the method.

Figure 1. Graphical representation of the links between the various

software parts within the compound database