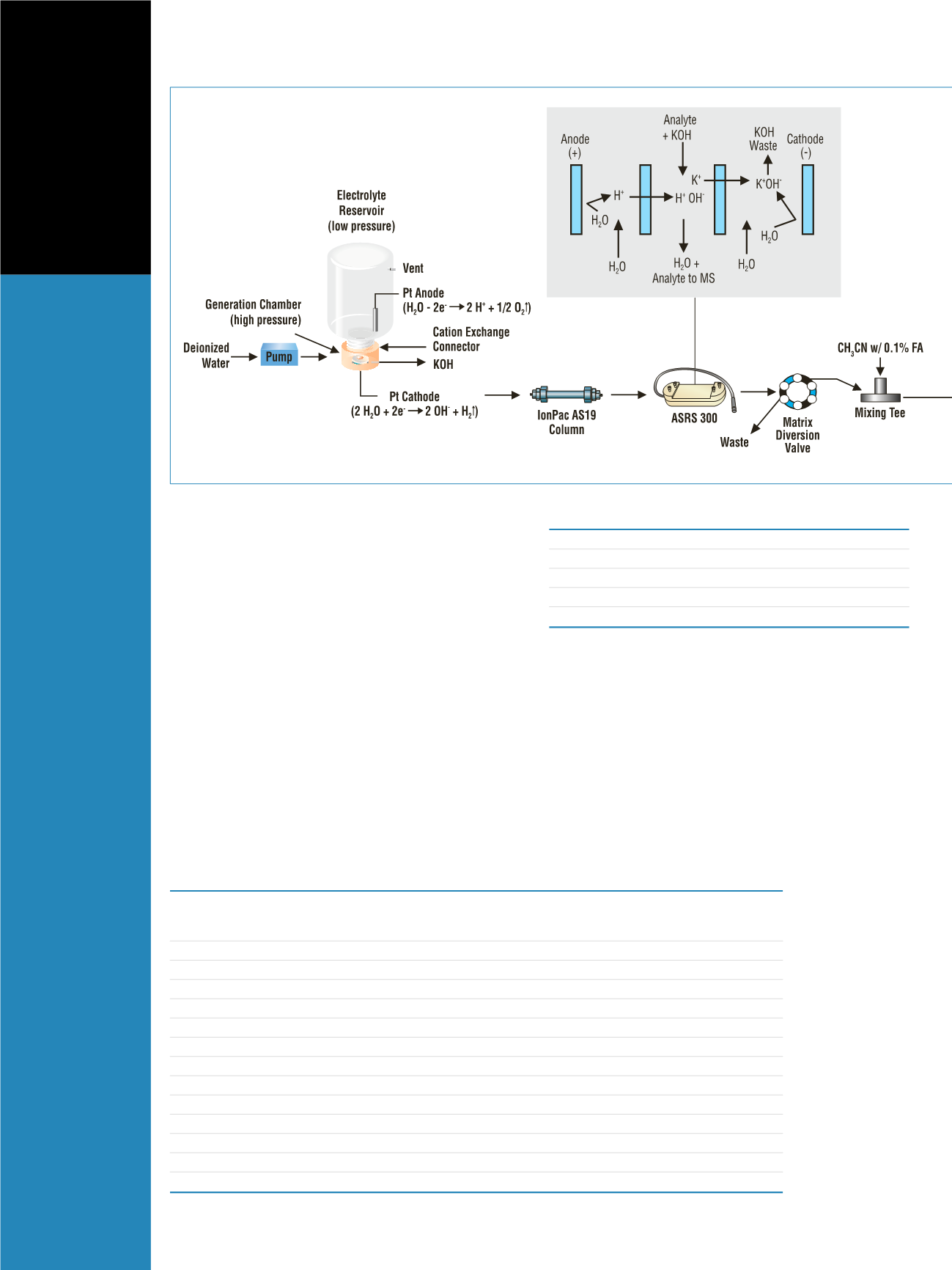

In addition, a matrix diversion valve was placed in

line prior to the mass spectrometer. This valve functions to

divert the high sample matrix waste from the MS source,

prolonging the time in between cleanings. Acetonitrile was

teed into the eluent stream after the matrix diversion

valve. The acetonitrile had two main purposes: to assist in

the desolvation of the mobile phase and to act as a make-

up flow when the IC eluent was diverted to waste.

Mass Spectrometry

MS analysis was carried out on a TSQ Quantum Access

™

triple stage quadrupole mass spectrometer with a heated

electrospray ionization (H-ESI) probe. The MS conditions

used are shown in Table 3.

Figure 1: Flow schematic of the IC-MS/MS system

Skimmer

Q1

Q3

CE

Tube Lens

Offset

Scan Time

Analyte

(m/z)

(m/z)

(V)

(V)

(V)

(s)

MCAA

93.01

35.60

10

26

0

1.25

MBAA

136.99

79.09

12

33

0

1.25

DCAA

127.02

83.20

11

26

0

1.25

DBAA

214.80

79.20

24

33

0

1.25

BCAA

171.00

79.20

35

44

0

1.25

TCAA

161.06

117.10

10

69

0

1.60

BDCAA

79.00

79.00

15

30

0

1.60

DBCAA

206.74

79.13

15

30

0

2.50

TBAA

250.70

79.10

25

26

0

2.50

MCAA-ISTD

94.01

35.60

10

26

0

1.25

MBAA-ISTD

138.00

79.09

12

33

0

1.25

DCAA-ISTD

128.01

84.20

11

26

0

1.25

TCAA-ISTD

162.06

118.10

10

69

0

1.60

Table 4. MS conditions for the various HAAs and internal standards

Ion source polarity:

Positive ion mode

Spray voltage:

4000 V

Sheath gas pressure:

40 units

Auxiliary gas pressure:

15 units

Capillary temperature:

270 °C

Table 3. Mass spectrometer conditions

Individual standards were infused into the mass

spectrometer to determine optimum tube lens settings and

collision energies for the product ions. Table 4 describes

the MS conditions for specific HAAs and internal

standards.