Thermo Scientific

| Reagents, Solvents and Accessories

5

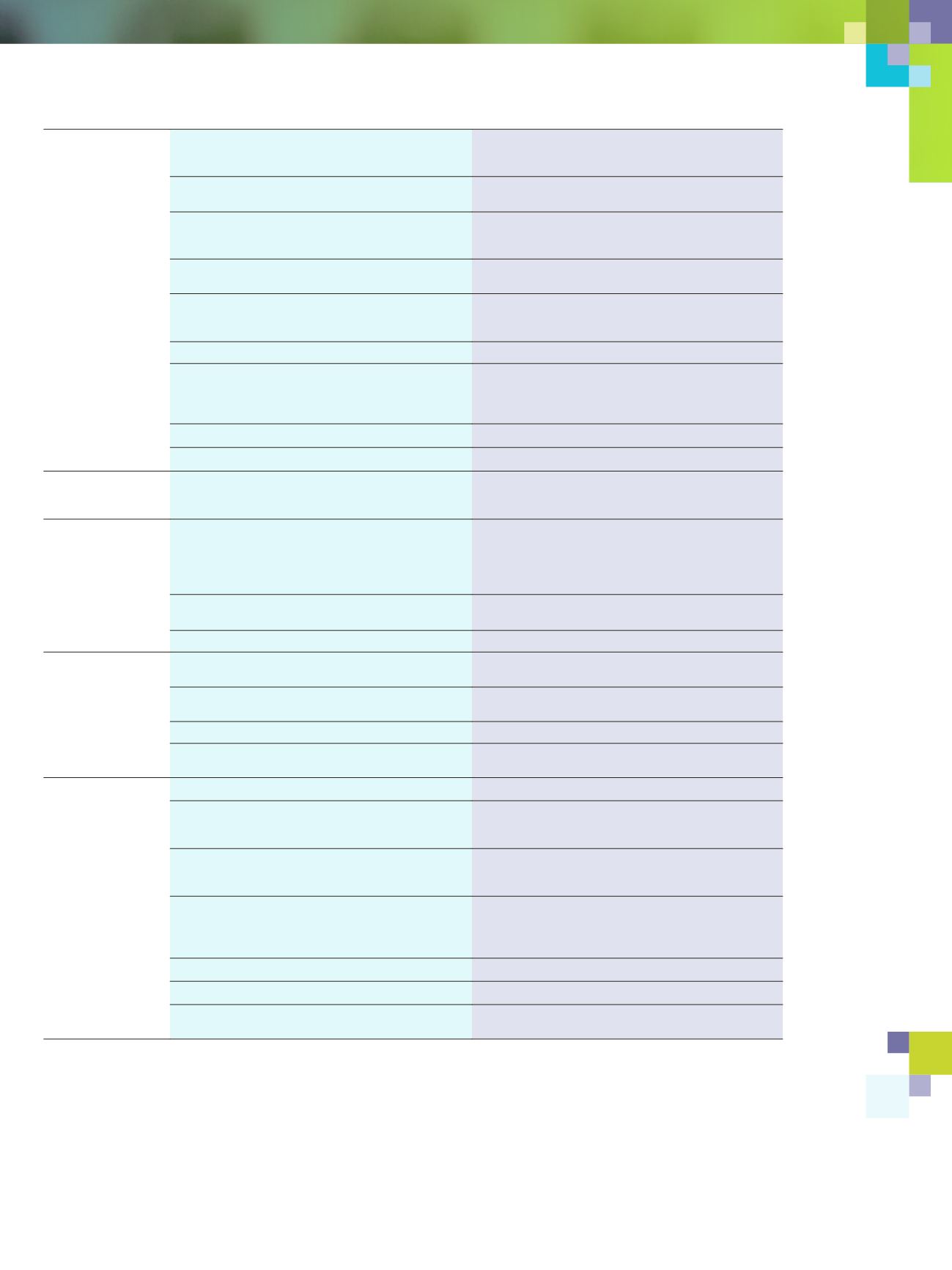

Derivatization Problem Possible Cause

Recommended Solution

Low Yield

Carrier, air, detector (FID) hydrogen or make-up gas flow set

incorrectly

Measure flows using a Thermo Scientific GFM Pro Gas Flow

Meter and set accordingly using instrument manufacturer’s

recommendations

Reagent deteriorated

Store reagent properly to prevent oxygen/water contamination,

temperature damage (refer to product specification sheet)

Rate of reaction too slow

Re-evaluate reagent concentration, time, temperature and consider

heating the reaction mix (consider the thermal stability of the

analytes and reagents)

Water in reaction mix

Remove water by adding sodium sulfate to sample. Store reagent

properly to prevent oxygen/water contamination

Improper handling technique: (e.g. Low boiling components could

be lost during sample concentration); sample too dilute; wrong

solvent

Re-evaluate technique, if possible eliminate steps in which analyte

could be adsorbed or otherwise lost (unnecessary transfers etc.)

Wrong reagent

Re-evaluate reagent selection and select more appropriate reagent

Impurities in solvent, starting material, catalysts, or extract

interfering with derivatization (e.g. Plasticizers from vial,

inorganics used in sample synthesis, preservatives or

antioxidants in solvents)

Use only highest purity material at all steps in the sample

preparation process

Reagent: sample ratio too low

Use more reagent for same amount of sample

Sample adsorbed to glassware

Deactivate glassware, inlet sleeve and column by silanizing

No sample separation

after adding reagent and

heating

Septum in reaction vial not sealed

Prepare a new sample and derivatize. Be sure that the vial is

sealed

Detector response low

Sample components absorbed by inlet liner or column

Inject standard on column known to be performing well. If results

are good, remove inlet liner and check cleanliness. Use new,

deactivated liner or replace glass wool and packing. Rinse bonded

phase column or remove a few cm from inlet end of non-bonded

column. If performance is not restored, replace column

Low yield of derivative - reaction did not go to completion

Add more reagent, increase temperature or heating time or add

catalyst. Water may be present; add sodium sulfate to sample

Detector (FID) dirty

Clean FID as per instrument manual

Extra peak(s)

Derivative reacting with solvent

Use a solvent that does not have an active hydrogen, alcohol or

enolizable ketone group (e.g. Hexane, toluene etc. )

Impurities from sample, solvent, reagents, sample vial, other

labware

Inject solvent and reagent blanks, solvent rinse from unused vial

etc. Isolate source of impurities

Reagents interacting with column

Verify that reagent is compatible with analytical column

Derivative undergoing hydrolysis

Remove water by adding sodium sulfate to sample. Store reagent

properly to prevent oxygen/water contamination

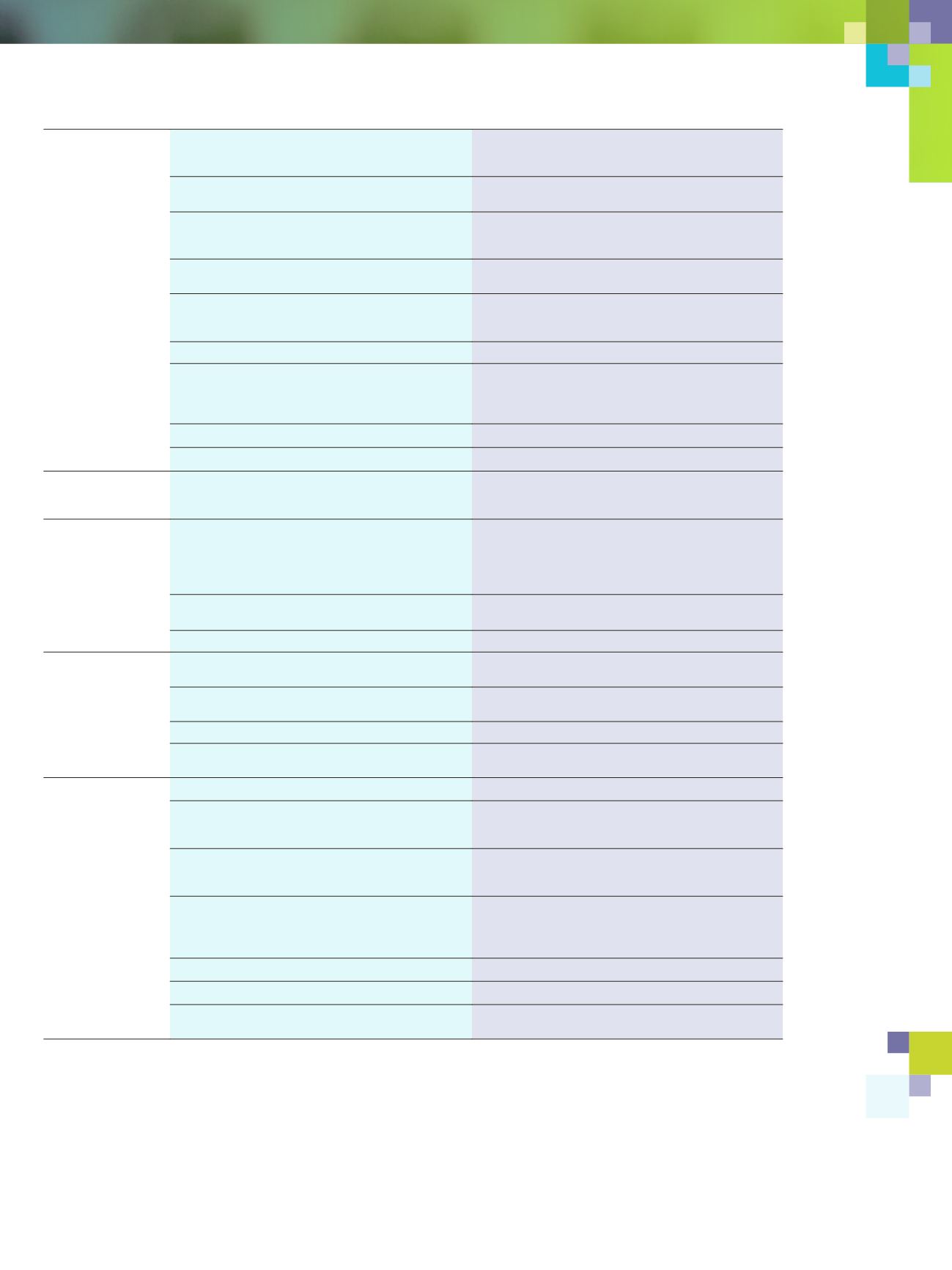

Missing peaks or

solvent peak only

Wrong reagent

Re-evaluate reagent selection

Reagent deteriorated

Store reagent properly to prevent oxygen/water contamination,

temperature damage (refer to product specification sheet for stor-

age conditions and reagent lifetime)

Rate of reaction too slow

Re-evaluate reagent concentration, time, temperature and consider

heating the reaction mix (consider the thermal stability of the

analytes and reagents)

Impurities in solvent, starting material, catalysts, or extract

interfering with derivatization (e.g. Plasticizers from vial,

inorganics used in sample synthesis, preservatives or

antioxidants in solvents)

Use only highest purity material at all steps in the sample

preparation process

Sample adsorbed to glassware

Deactivate glassware, inlet sleeve and column by silanizing

Reagent: sample ratio too low

Use more reagent for same amount of sample

Water in reaction mix

Remove water by adding sodium sulfate to sample. Store reagent

properly to prevent oxygen/water contamination

Troubleshooting