4

The Use of A New Meta-calculation Software for Automated Data Processing of Tandem MS for Inborn Error Metabolism Research

hase of

is.

process

lysis of

s were

ltiple-

as, 1,000

greement

from hours

h started

gy, more

ample

nal

of

ure 1).

Research

Claudio De Nardi

2

, Marta Kozak

1

,

tz

3

, David C. Kasper

4

, Chengya Liang

1

FIGURE

concent

FIGURE

area fro

Software Calculation:

The SRM transitions for each analyte and

internal standard are entered in the software for data analysis; IS

concentration and analyte/IS relative response factor are also entered

to calculate analyte concentration.

User defined formulas can be created to perform calculations using

peak areas or analyte concentrations.

Upper and lower concentration limits can be set for each analyte;

different values can be used for unknown and quality control samples;

the software will flag samples outside these acceptance ranges. The

same applies to user defined formulas.

A processing method is created by selecting the peak areas, analyte

concentrations and user defined formula results that will be displayed

by the software. Results can be exported in Excel or text format.

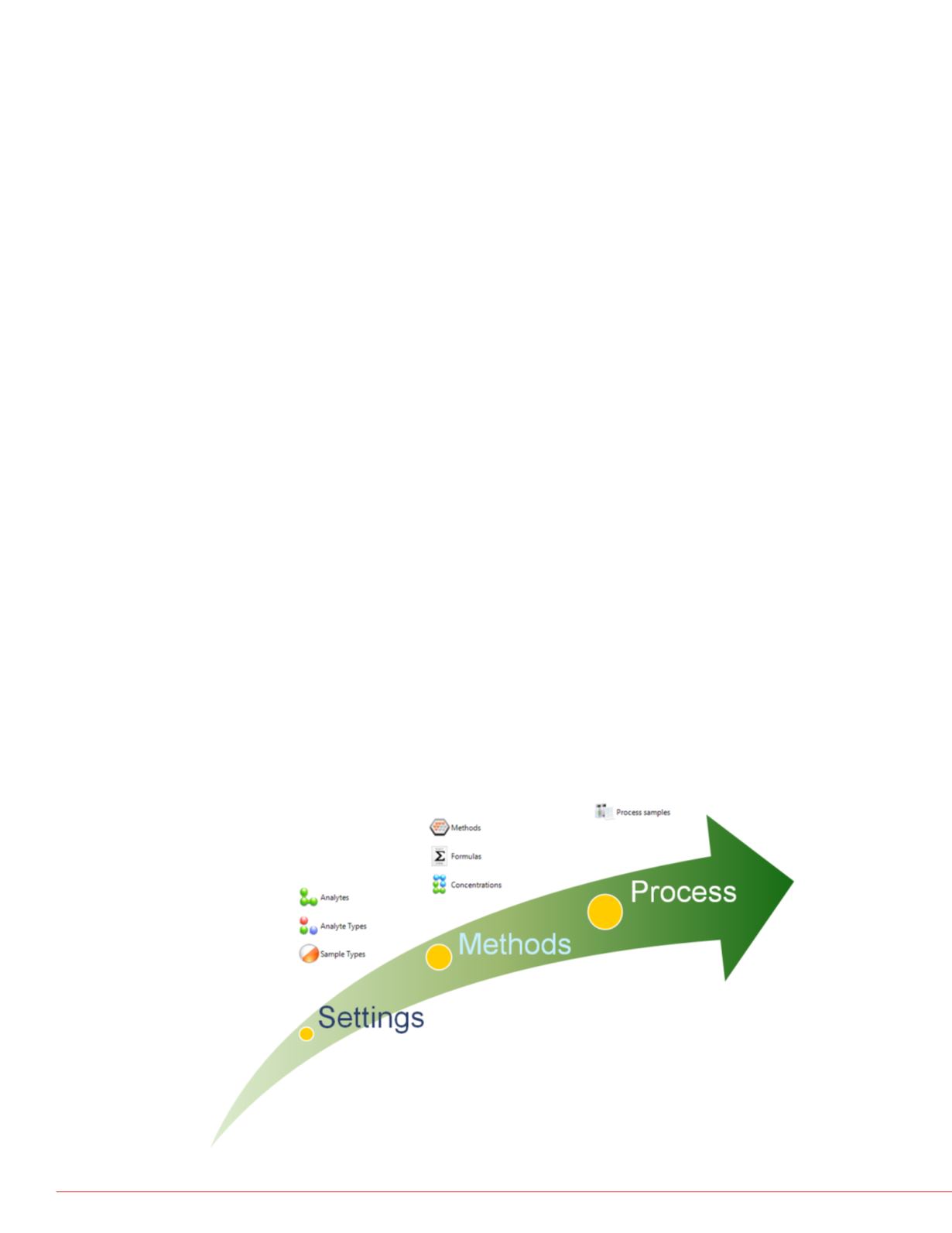

As depicted below, Figures 2 shows the workflow of software, and

Figure 3 shows workflow comparison between software and manual

process.

FIGURE 2. Intuitive Workflow – icon based User Interface

sting

FIGURE 3. Workflow Comparison between Software and Manual

Approach

Figures

Data Analysis

Manual Calculation:

Manual calculation was performed by creating

a processing method to extract chromatograms and calculate peak

areas for each analyte and IS using Thermo

Scientific™Xcalibur™

software.

Peak areas were exported in Excel (Microsoft Co.) format and copied

and pasted into an Excel worksheet setup to calculate analyte

concentrations and values based on the same formulas used by the

meta-calculation software.

For

Concen

(User D

For

Peak

(User D