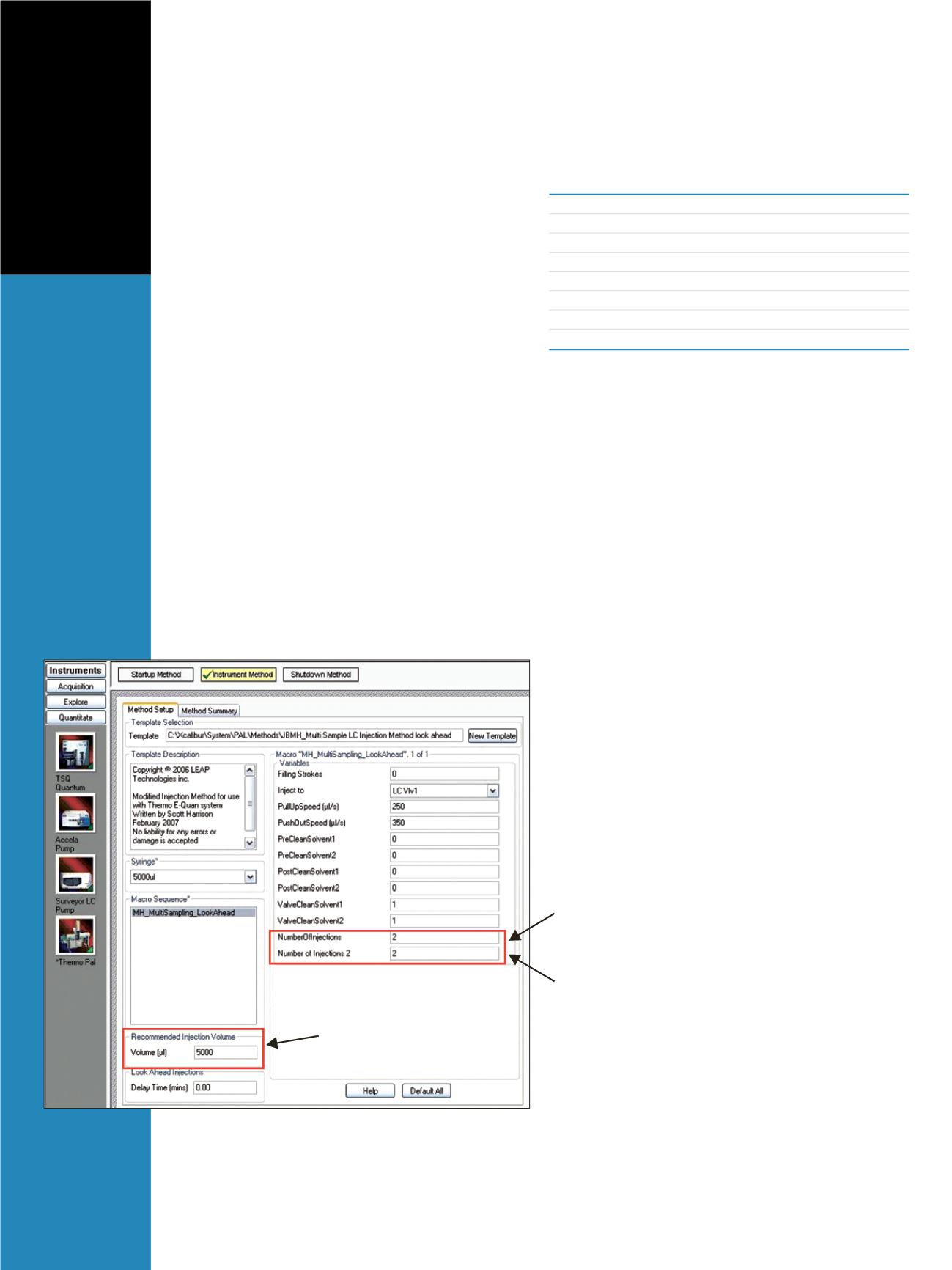

Figure 2: The method setup screen for the CTC Autosampler, showing the

capability to perform multiple injections from the same vial. The red box

highlights the parameters used to control the number of syringe fills from

two consecutive vials. In this example, a total of 20 mL will be injected.

Slightly different LC programs were used in each

method, depending on the volume of the sample injected.

The loading pump flow rates ranged from 1 mL/min for

1 mL samples to 5 mL/min for 20 mL samples. This allowed

the run times at the higher injection volumes to be shortened

because the time to transfer the sample from the sample

loop to the loading column depends on the flow rate. The

same LC program was used for the analytical column.

Two HPLC pumps were used for the analysis: one for

transferring the sample from the injection loop to the

loading column, and one for back flushing the compounds

off of the loading column and separating them on the

analytical column. The loading pump was a Surveyor Plus

™

LC pump (Thermo Fisher Scientific, San Jose, CA) and the

analytical pump was a U-HPLC Accela

™

pump (Thermo

Fisher Scientific, San Jose, CA).

The HTC autosampler was equipped with a 5 mL

syringe. To accommodate larger injection volumes (> 5 mL),

a CTC

™

macro sequence was programmed to allow for

multiple syringe fills and deliveries to the sample loop

from a 10 mL vial. For 20 mL samples, two 10 mL vials

were used and the macro allowed sampling from adjacent

vials filled with the same sample. The macro is shown in

Figure 2. Because this multi-sampling scheme can be quite

time consuming, the ability to perform “look-ahead”

injections allows for significant time savings. The loop

can be switched to an offline position during a run, and

subsequent samples can be prepared and injected while a

sample is being run.

MS

MS analysis was carried out on a TSQ Quantum Access

™

triple stage quadrupole mass spectrometer with an

electrospray ionization (ESI) source (Thermo Scientific,

San Jose, CA). The MS conditions were as follows:

Ion Source Polarity:

Positive ion mode

Spray Voltage:

4000 V

Ion Transfer Tube Temperature:

300 °C

Sheath Gas Pressure:

30 arbitrary units

Auxiliary Gas Pressure:

5 arbitrary units

Collision Gas (Ar):

1.5 mTorr

Q1/Q3 Peak Resolution:

0.7 Da

Scan Width:

0.002 Da

Quantitative and qualitative data were collected in the

same run and data file.

Results and Discussion

Chromatograms of the herbicide simazine at three different

injection volumes are shown in Figure 3. A very small peak

can be seen for the 1 mL injection volume; however, the

integration is not shown in the chromatogram. Injections

at higher volumes show superior signal-to-noise ratios and

intensity, which allow for analysis of very low concentration

samples (pg/mL and sub pg/mL). To test the reproducibility

of the multiple syringe fill method with a 20 mL loop,

eight replicate injections were performed using the 1 pg/mL

calibration standard. The results of this study are shown

in Table 1. No internal standard was used in this analysis;

however, if one were to be included, the % Relative

Standard Deviations (RSD) values would likely improve.

Table 1 also shows the peak areas and calculated difference

in peak areas between the 1, 5, and 20 mL injections.

FPO

Volume to be pulled

per syringe “injection”

Number of syringe

fills from the first vial.

Number of syringe fills

from the second vial (optional).