5

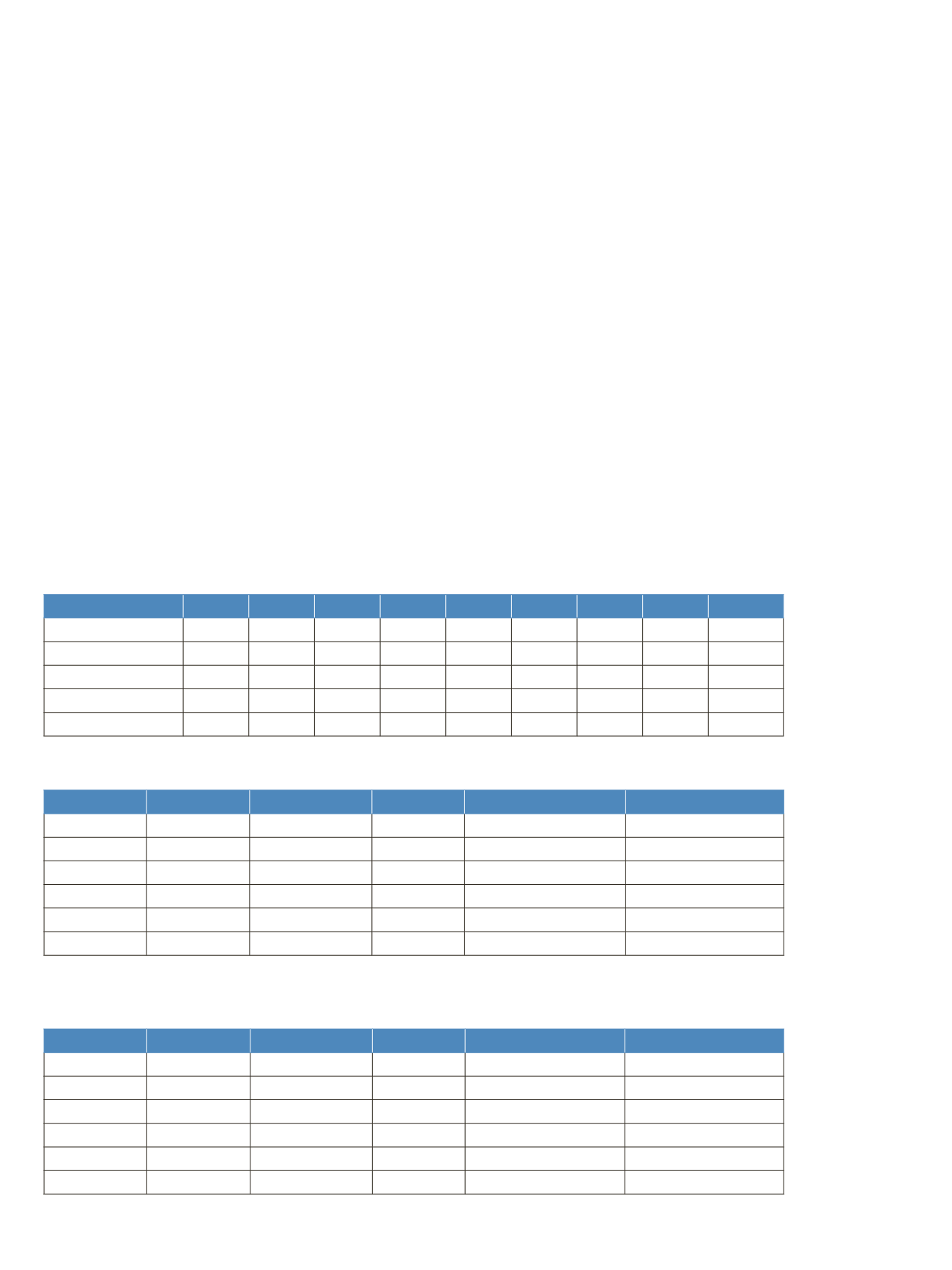

Another sample was prepared from beer that has

been spiked with different amounts of nitrosamines.

All nitrosamine compounds have been detected and

quantified in a low concentration range of 9 – 13 ppb, see

Table 5. Each quantified peak passed the ion ratio quality

control and could be positively confirmed at this low

level by calculating the product ion ratios for each of the

compounds.

Conclusions

With the described GC-MS/MS method on the TSQ 8000

system all nitrosamine compounds under investigation

could be safely detected and precisely quantified at the

required low levels for a safe food control.

The LODs of all compounds have been determined to be

below 1 ppb, using 1 ppb as the lowest concentration for

the quantitative calibration.

The TSQ 8000 GC-MS/MS shows a wide linearity in

the range of 1-500 ppb with very good precision. All

calibration curves have been shown to be strictly linear

with R

2

better than 0.99.

The TSQ 8000 GC-MS/MS shows great ion ratio stability

for the confirmation of positive samples. The RSD% of

the ion ratio of all compounds is lower than 4% even at

LOQ level.

The use, setup and maintenance of a GC-MS/MS method

for nitrosamines is easy. The unique AutoSRM software

finds and optimizes the SRM transitions and collision

energy automatically, even facing new and yet unknown

components.

Based on the demonstrated GC-MS/MS method, the

TSQ 8000 GC-MS/MS can successfully quantify the

concentration of nitrosamine components in real samples

without any uncertainty.

The described GC-MS/MS method for food nitrosamines

on the TSQ 8000 GC-MS/MS can serve as a turnkey

method for routine use in food safety control. It is using

standard GC-MS/MS triple quadrupole instrumentation

which is also common for many other areas of regular

food safety control, e.g. pesticides, POPs or polyaromatic

hydrocarbons. The presented method is fast, allows high

sample throughput, and provides results with very high

sensitivity and precision. With this standard EI ionization

method setup this presented method for low level

nitrosamine quantitation is recommended to be employed

as a productive alternative to the earlier described

chemical ionization ion trap procedure using liquid CI

reagents.

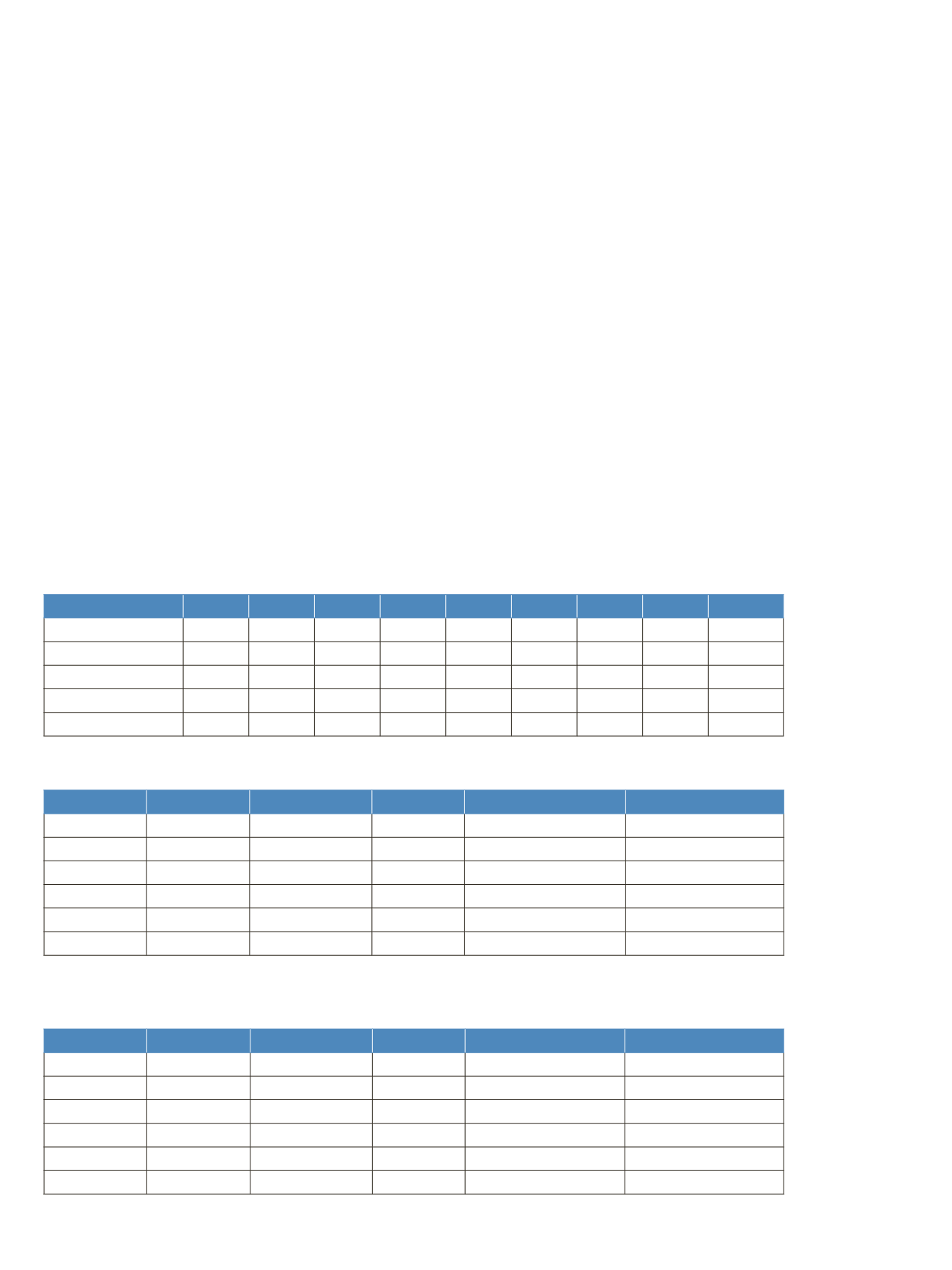

Concentration (ppb)

1

5

10

25

100

250

500

AVG RSD (%)

NDMA

70.7

67.9

68.0

69.8

69.1

71.9

69.6

69.6

2.01

NDEA

20.8

22.1

22.5

22.4

22.5

22.5

22.5

22.2

2.84

NDBA

102.4 102.4

98.2

98.6

96.1

93.4

99.2

98.6

3.28

NPIP

6.1

5.5

6.2

5.9

6.0

6.1

6.2

6.0

3.88

NPYR

-

64.6

62.4

66.2

66.9

68.1

66.7

65.8

3.06

Table 3. Precision of the confirming ion ratios from 1 ppb – 500 ppb

Compound

Area

ISTD Area

Area Ratio Ion Ratio Confirmation Calculated Amount (ppb)

NDMA

2591.368

2028129.842

0.001

Pass (65.1%)

0.74*

NDEA

1875.386

2028129.842

0.001

Fail (0%)

N/A

NDBA

6806.996

2028129.842

0.003

Fail (81.1%)

N/A

NPIP

N/A

2028129.842

N/A

N/A

N/A

NPYR

N/A

2028129.842

N/A

N/A

N/A

NMOR

4415.782

2028129.842

0.002

Fail (0%)

N/A

Table 4. Results of a blank sample

*Below LOQ

Compound

Area

ISTD Area

Area Ratio

Ion Rato

Calculated Amount (ppb)

NDMA

91318.135

2282168.009

0.040

Pass (68.3%)

12.0

NDEA

480955.478

2282168.009

0.211

Pass (22.0%

9.4

NDBA

402754.561

2282168.009

0.176

Pass (96.8%)

13.2

NPIP

280162.125

2282168.009

0.123

Pass (5.9%)

10.1

NPYR

318081.273

2282168.009

0.139

Pass (68.9%)

13.3

NMOR

1145719.054

2282168.009

0.502

Pass (67.9%)

10.1

Table 5. Results from a spiked beer sample