2

injected via autosampler for analysis. For recovery and

validation studies 15 g of the "churna" was fortified with

appropriate quantities of the pesticide standard mixture.

Calibration

Stock standard solutions of each pesticide compound

were prepared by weighing 10±0.1 mg, dissolving in

10 mL acetonitrile and storing the solution in amber-

colored glass vials at -20

℃

. A total of ten intermediate

mixtures (each containing 15-20 compounds) of 10 mg/L

concentration were prepared by diluting an adequate

quantity of each compound in acetonitrile. A working

standard solution (1 mg/L) was prepared by mixing an

adequate quantity of intermediate standard solution

and dilution with acetonitrile and storing the solution at

-20

℃

. The calibration standards at 2.5, 5, 10, 25 and

50 µg/L were freshly prepared for measurement of the

calibration curves. The calibration graphs (five points)

for all the compounds were obtained by plotting the

individual peak areas against the concentration of the

corresponding calibration standards.

Instrument and Method Setup

The analytical method comprises the sample handling

using the Thermo Scientific

TM

TriPlus

TM

RSH liquid

auto sampler, the Thermo Scientific

TM

TRACE

TM

1300

Series gas chromatograph equipped with a temperature

programmable PTV injector, and the Thermo Scientific

TM

TSQ 8000

TM

triple quadrupole GC-MS/MS system. The

instrument method parameters are summarized in Table 1.

The Thermo Scientific

TM

TraceFinder

TM

software

was used for method setup and data processing. The

TraceFinder software provides a compound database of

pesticides compoundsof more than 800 compounds with

all required analytical details such as retention times and

the optimized SRM transitions for data acquisition and

processing. These software features were employed to

create the processing method for the screening a large

pesticides compound list

[2]

.

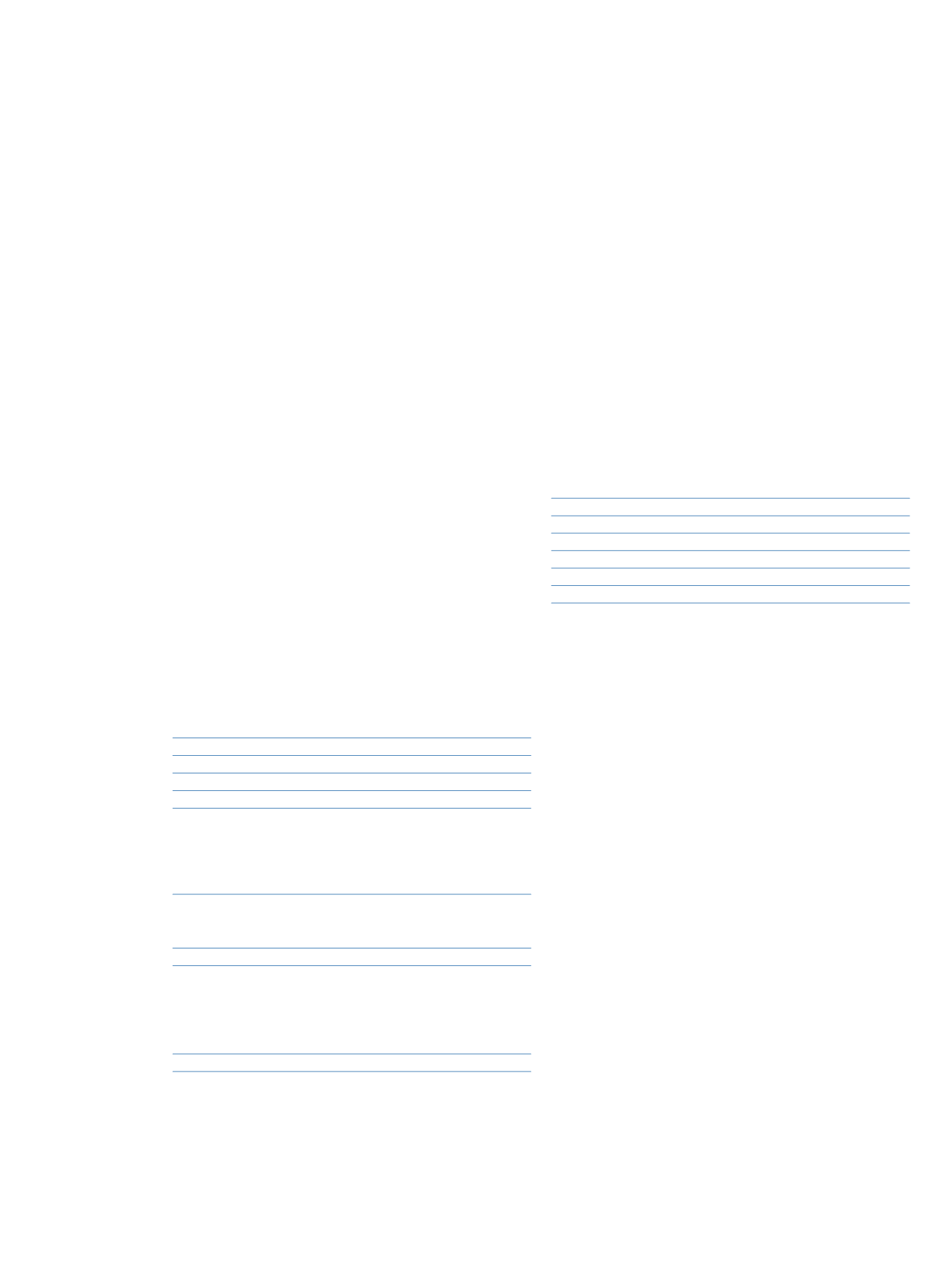

For all pesticide compounds two SRM transitions were

chosen for the overall MRM acquisition method. The

first transition was used for quantitation, the second

transition for confirmation by checking the ion intensity

ratio by the TraceFinder software during data processing.

Retention times had been synchronized between data

processing of standards with the acquisition method for

the timed-SRM protocol (see Figure 2) in order to lock

all compound retention times for robustness independent

on the impact of the matrix carried by real life sample.

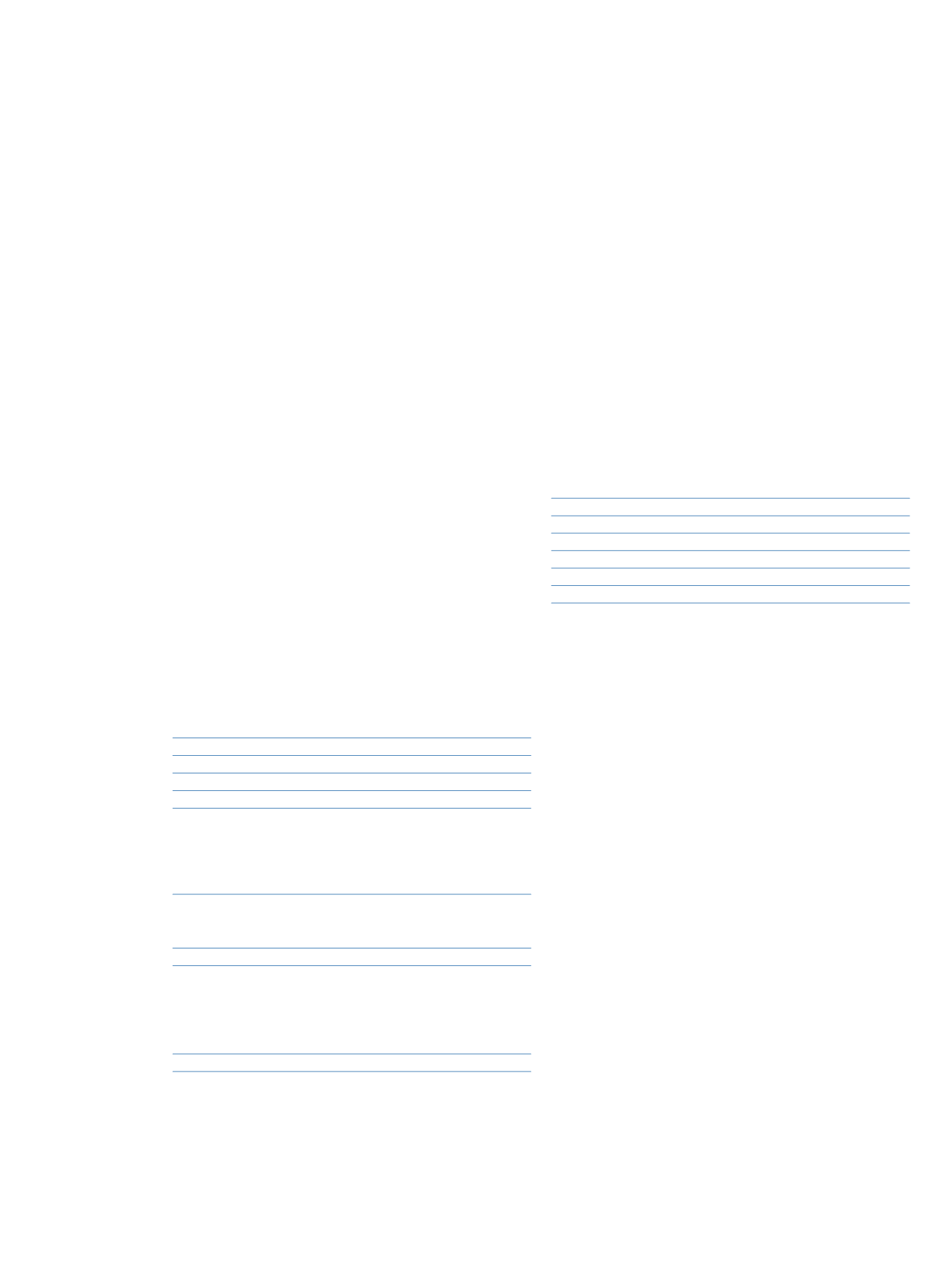

TABLE 1. Instrument method parameters.

TRACE

TM

1310 Gas Chromatograph Parameters

Carrier gas

Helium

Injector

PTV

Mode

splitless

Splitless time

3 min, split flow: 30 mL/min

PTV program

87

℃

, 0.3 min (injection)

14.5

℃

/min to 285

℃

(transfer)

285

℃

, 2.5 min (transfer)

14.5

℃

/min to 290

℃

(cleaning)

290

℃

, 20 min (cleaning)

Column

Thermo Scientific TraceGOLD

TM

TG-5 SilMS, 30 m x 0.25 mm x

0.25 µm (p/n 10177894)

Column flow

1.2 mL/min, constant flow

Oven program

70

℃

, 2 min

10

℃

/min to 200

℃

200

℃

, 1 min

10

℃

/min to 28

℃

285

℃

, 8.5 min

Injection

3 µL by TriPlus RSH Autosampler

TSQ-8000 MS/MS Parameters

Ion source temperature

230

℃

Interface temperature

285

℃

Acquisition mode

EI, 70 eV

MRM detection

Timed SRM mode (see Figure 1)

Acquisition rate

500 ms

MRM parameter

See Table 1

The timed-SRMacquisition method used with the TSQ 8000

MS avoids the laborious and time-consuming process of

segment creation and method maintenance.The scan times

are automatically calculated based upon the specified

cycle time so that uniform cycle times are obtained

for each mass transition, thus reducing the extensive

optimization process for scan times and data points

across a peak. The dwell times for data acquisition are

maximized independently for the number of compounds

in the MRM method. Table 2 lists the MRM parameters

for the compounds analyzed in this method.

The data processing and reporting was done using the

quantitation and reporting suite. The software allows

retention time locking by synchronization between

the data processing and the acquisition setup for all

compounds in the method.