Introduction

Ayurveda is a Sanskrit term, made up of the words

"ayus" and "veda. "meaning life and science; together

translating to 'science of life'. A blend of several herbs

and spices make up the powdered mixture known as

"churna". Depending on its intended use for medicinal,

beauty, or culinary purpose, the recipe varies. Avipittakara

"churna" is a traditional Ayurvedic formula used

widely and almost daily to control vitiated pitta dosha,

remove heat in the digestive system, control indigestion,

constipation, vomiting and anorexia. A major analytical

challenge for these types of samples is mainly addition

of multiple herbs with sugar and the natural color of

herbs

[1]

.

The dried leaves result in highly complex extracts from

the sample preparation due to the rich content of active

ingredients, essential oils and the typical high boiling

natural polymer compounds. Due to the use of pesticides

in the fresh herbs, the "churna" may contain residual

pesticides. Analysis of pesticide residues is thus important

and governmentally regulated

[2]

. Strict quality parameters

have been mented to preserve the quality and efficacy of

these "churnas".

Sample Preparation

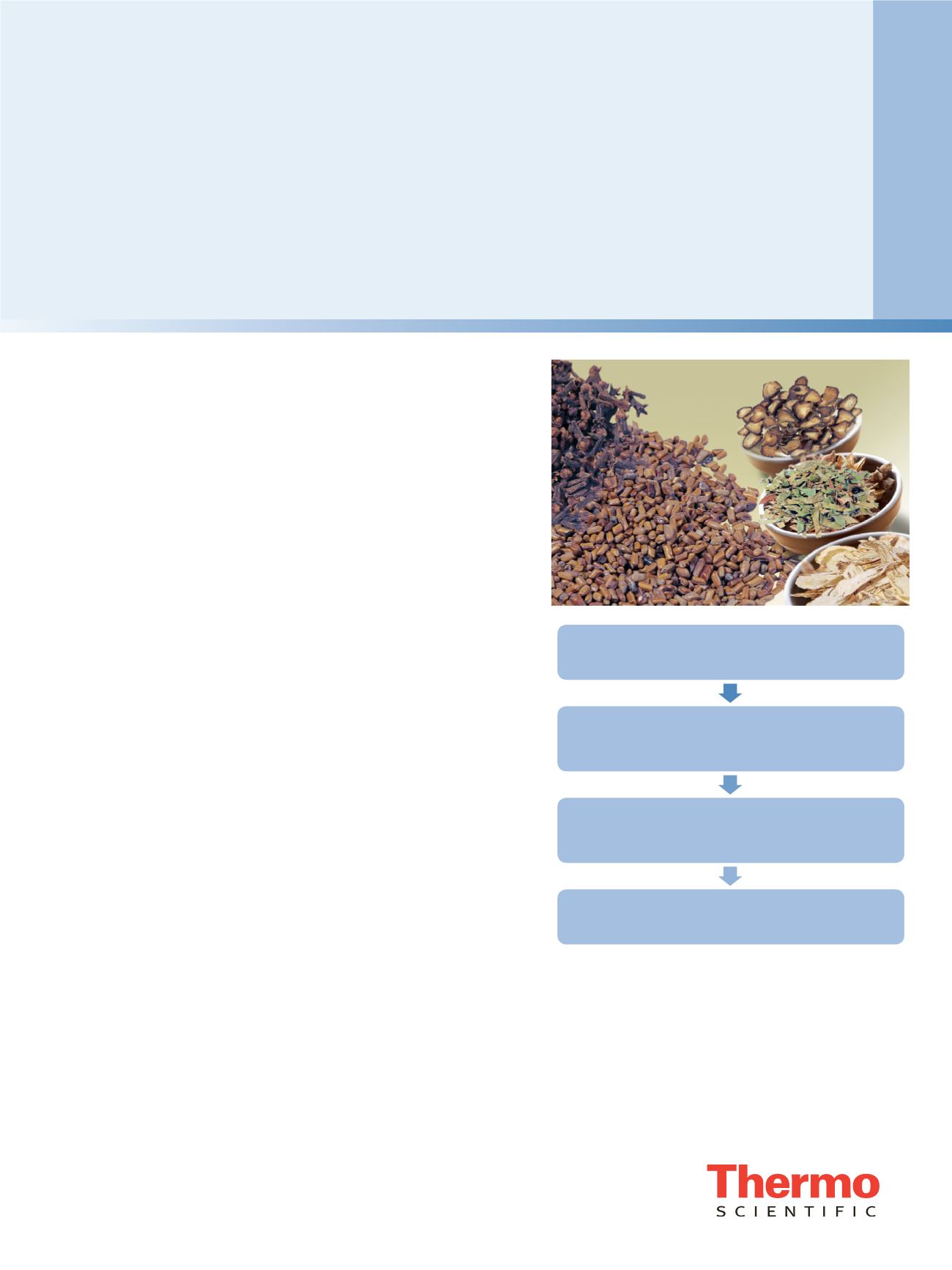

In brief, the QuEChERS sample preparation (see Figure

1) involved the extraction of 15 g of a powder sample

of Avipittakara "churna" with 15 mL acetonitrile

(containing 1% acetic acid) in the presence of 3 g

magnesium sulfate, 1.5 g sodium acetate and 1 g NaCl.

The supernatant (1 mL) was collected after centrifugation,

and dispersive cleanup was performed using 200 mg

PSA and 10 mg GCB. The extract was centrifuged at

10 000 rpm for 5 min, and 3 µL of supernatant was

Figure 1. Sample preparation for extraction of pesticides from

ayurvedic churnas

Analysis of Multi-Residue Pesticides Present in

Ayurvedic Churna by GC-MS/MS

Manoj Surwade

1

, Sunil T Kumar

1

, Aarti Karkhanis

1

, Manish Kumar

1

, Soma Dasgupta

1

, Hans-Joachim Huebschmann

2

,

1

Thermo Fisher Scientific, Mumbai, India;

2

Thermo Fisher Scientific, Singapore

Keywords:

Traditional herbal medicine, fast liquid/liquid extraction,

QuEChERS, timed-SRM, retention time synchronization, MRM, ion

ratio confirmation, TraceFinder data processing

Technical Support Note-000

Detection, Identification, and Quantitation of

zo Dyes in Leather and Textiles by GC/MS

Adi Purwanto

1

, Alex Chen

2

, Kuok Shien

3

, Hans-Joachim Huebschmann

3

PT Alpha Analyti al Indonesia, J karta,

2

Alp a Analytical Pte., Singapore,

3

Th rmo Fisher Scientific,

Singapore

tr duction

zo dyes are compounds charact rized by their vivid

color and provi e exc llent colori g properties. They

a e important and widely used as coloring agents in the

textile and le ther industries. The risk in the use of zo

dyes arises mainly from the break own pr ducts that can

created

in vivo

by reductive cl avage of the azo group

into aromatic amines. Due to th toxicity, c rcinogenicity

an pote ti l utagenici y of thus forme aromatic

amines, the use of certain azo dy s as textile and l ather

lorants, a d the exposure of consumers using the extile

and ather colored with azo compounds causes a serious

health concern

[1]

. The two m i routes of consumer

expo ure are the skin absorption of the azo compounds

from the dyed clothes worn, and potential oral ingestion,

mainly referring to the sucking of textil s by b bies and

young children. The man facturing workers can also b

exposed via the i h lation route.

The EU Commis ion classified 22 amines as p oven

or uspected human carcinogens. “Azo dyes which, by

reducti cleavage of one or more azo groups, m y release

one or more of hese aromatic amines in detectable

conc ntratio s, i e. above 30 ppm in the finished articles or

in the dyed parts thereof … may not be used in textile and

le ther articles which may come into direct and prolonged

contact with the human skin or oral cavity”

[2]

. The EU

Directive 2002/61/EC has banned the use of dangerous

azo colorants, placing textiles and leather articles colored

with such substances on the market, and requested the

development of a validated analytical methodology for

control. Since the azo dyes are one of the longest known

synthetic dyes, simple and inexpensive in preparation,

available easily in bulk and in great variety, and rarely

cause acute symptoms, the textile manufactures can be

persuaded to use them despite the regulations — if the

strict and reliable analytical control is not imposed.

Experimental Conditions

Sample Preparation

The sample preparation for the analysis of textile samples

depends on the nature of the textile. The textiles made of

cellulose and protein fibers, for example cotton, viscose,

wool, or silk

[3]

make the azo dyes accessible to a reducing

agent without prior extraction. The EN ISO 17234-1

standard method for the analysis of such textiles is based

on the chemical reduction of azo dyes followed by solid

phase extraction (SPE) with ethyl acetate providing a

ready-to-inject extract after solvent concentration.

The analysis of synthetic fibers like polyester, polyamide,

polypropylene, acrylic or polyurethane materials requires

prior extraction of the azo dyes and is described in the

EN 14362-2 standard method. The analysis of leather

samples follows the EN ISO 17234 standard meth d.

The azo group of most azo dyes can be reduced in the

presence of sodium dithionite (Na

2

S

2

O

4

) under mild

conditions (pH = 6, T = 70 °C), resulting in the cleavage

of the diazo group and formation of two aromatic amines

as the reaction products. The amines are extracted by

liquid-liquid extraction with t-butyl methyl ether (MTBE),

concentrated, adjusted to a certain volume with MTBE,

then analyzed by GC/MS. The quantitation is performed

:

azo yes, canc rogenic am s, tex iles, leather, EN ISO

standard method, ISQ Series GC/MS, fast full scan detection, quantitation,

confirmation, library se rch

.

Application No e 10329

A

o

0361

Weigh 15 g of

Churna

15 mL acetonitrile (with 1% acetic acid) was added, shaken

well.Further 3 g MgSO

4

+1.5 g NaOAc+1 g NaCl was added

and homogenized using a Vortex mixer

After centrifugation (5000 rpm, 5 min), cleanup of 1 mL

up rnatant performed by dispersive SPE using 200 mg PSA

and 10 mg GCB

Centrifuge t 1000 rpm f r 5 min, 3 μL of supernatant

inj cted to GC-MS/MS